General Introduction Of Aluminum PCB

Introduction

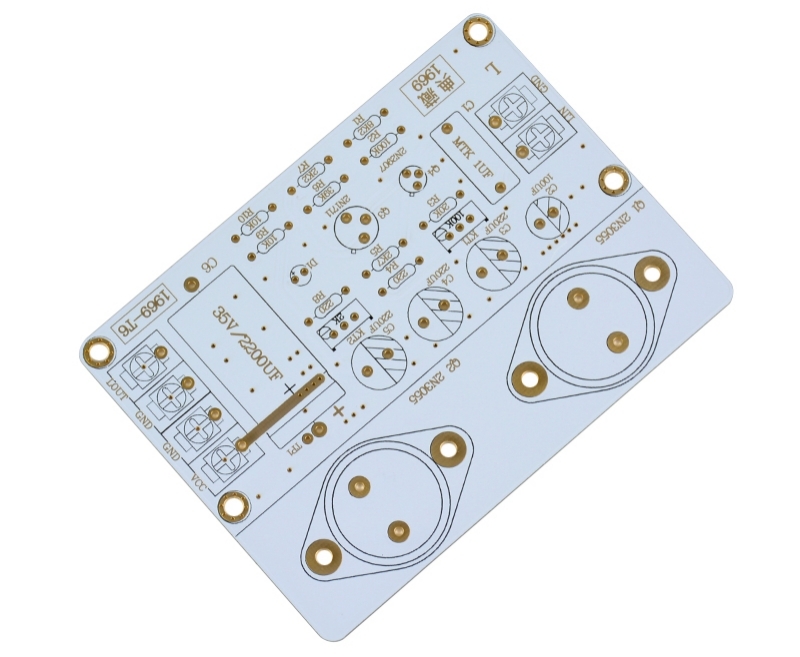

Printed circuit boards, also known as PCBs, are commonly used in various electronic devices. Depending upon their application, the metal core PCB may be made of multiple metals. However, the most common kind of metal chosen for the manufacturing of a PCB is aluminum.

Aluminum PCB is known for its excellent performance and capability and offers a better alternative among other metal core PCB options. You must read them below if you are also interested in learning more about aluminum PCB boards and their details.

What Is Aluminum PCB?

The primary reason which makes aluminum PCB a better choice for PCB manufacturing is the fact that it is capable of dissipating heat. Electronic devices usually release a lot of heat, so heat dissipation is significant to keep them stable and functional.

It comes with an aluminum core, and FR4 further follows it. There is a thermal clad that acts as a layer and dissipates the heat accordingly. The main aim is to offer a cooling mechanism for the components; hence, the device's performance tends to increase.

The main aim of choosing an aluminum PCB board is that it proves to be suitable for such devices that work on high power and require tight tolerance to enhance the life of the device.

Advantages and disadvantages of Aluminum PCB

Aluminum PCBs are gaining significant popularity; however, everything with certain benefits also offers some downsides. Similarly, when it comes to aluminum PCB material, it also has certain advantages and certain disadvantages to offer, and these are provided below:

Advantages of Aluminum PCB

Some of the features of an aluminum PCB comprise the following advantages that make it suitable for incorporating into different electronic devices:

Lightweight Solution

The primary consideration that most electronic device manufacturers take into consideration is that the PCB they have installed in their devices amounts to a lighter weight.

The lighter weight of PCB also reduces the actual device's weight and offers it a compact structure, which is the need of today's devices. Hence, choosing aluminum PCB provides a lightweight solution for most electronic devices.

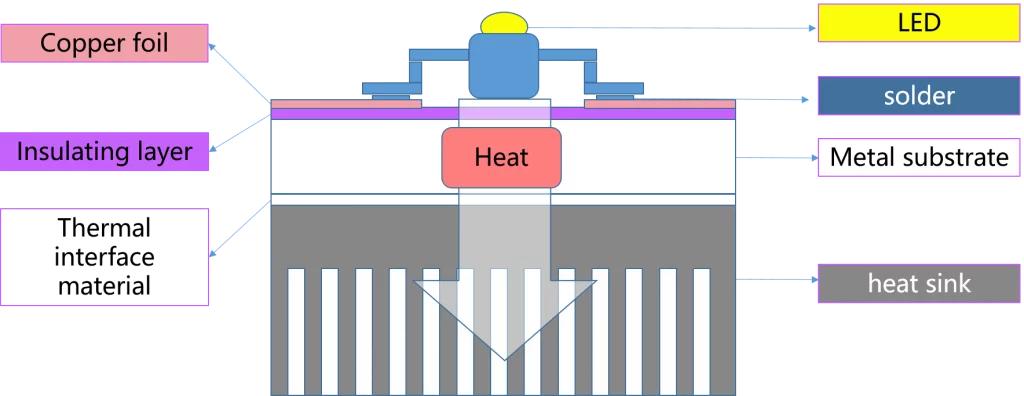

Dissipation of Heat

Heat dissipation is also a significant factor for every PCB installed in the electronic component. All kinds of electronic components tend to release heat. Some of them release a massive amount of heat, and some of them don't. So, when choosing aluminum PCB material, one can rest assured that it will dissipate the heat to a greater extent.

Other metal core PCBs also tend to dissipate heat but not as much as aluminum ones, so choosing this PCB offers a better solution.

Durable Choice

The stable structure is an essential thing to take into consideration. If the PCB chosen is not durable, the electronic device will also lose its durability. Hence, aluminum offers a durable finish and long-lasting life, which makes it suitable for use in the longer run.

Therefore, most aluminum PCB manufacturers prefer choosing aluminum as the finest material for PCB manufacturing.

Positive Impact on the Environment

Due to the increasing focus on environmental practices worldwide, PCB manufacturers are of the view to choose a material that is suitable for the environment in PCB manufacturing.

When it comes to aluminum, it proves to be the ideal choice. It is free from all kinds of toxins, and the assembly process also doesn't cause any damage to the environment. Hence, when choosing aluminum PCBs, the significant advantage they offer is that they are environmentally friendly.

Cost-Effective Solution

Manufacturing aluminum PCBs is a very economical choice. The aluminum material is widely available and cheaper than the other options. Hence, every aluminum PCB manufacturer offers a cost-effective PCB for most electronic devices.

In cases where budget constraints are present and in a limited budget, maximum benefits need to be enjoyed, choosing an aluminum PCB is a better one.

Disadvantages of Aluminum PCB

Where aluminum PCBs offer ample advantages, there are certain limitations on their part, which need to be borne in mind when choosing them for your electronic devices. These limitations are discussed below:

Lack of Double Layer

Compared to other standard PCBs, aluminum PCBs do not have a double layer. Until now, they have been operational with a single layer only. Creating a double layer is difficult for aluminum PCB manufacturing companies.

Minor Glitches

Despite being quite efficient in performance and capabilities, aluminum PCBs still need to improve in some areas. Hence, these aluminum PCBs might offer some electrical strength and pressure issues at specific points.

Structure of Aluminum PCB

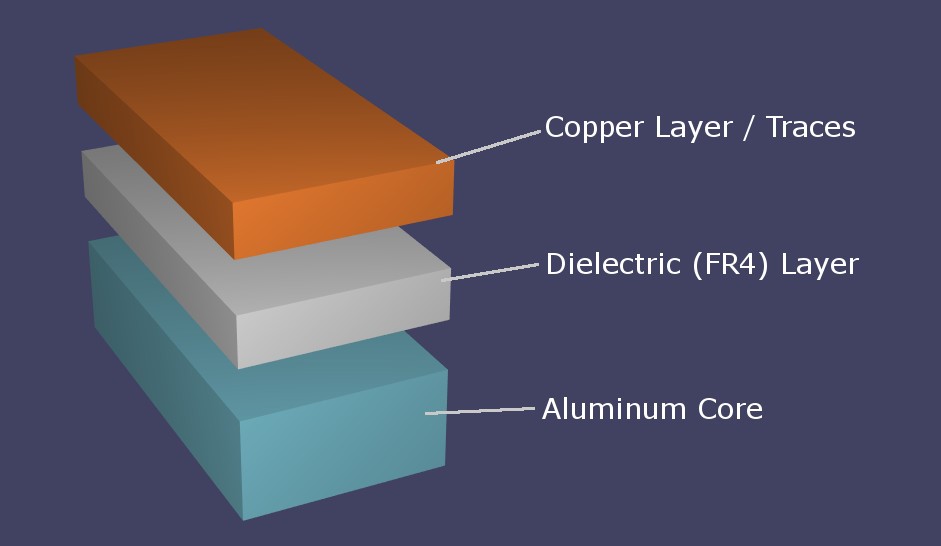

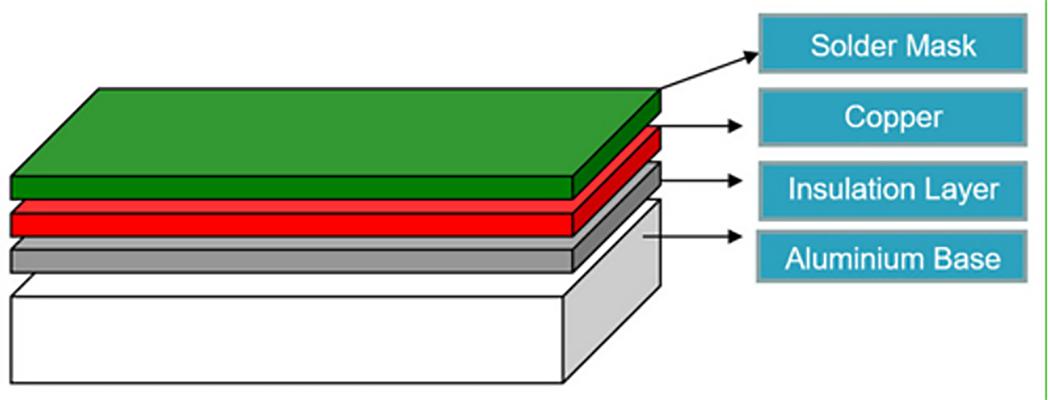

Aluminum PCB is manufactured in a way that it has three different layers. Below, the entire structure of the metal core aluminum PCBs is provided:

Circuit Copper Layer

A copper layer is first etched to create an aluminum PCB. This layer uses a copper foil and adds a thickness similar to FR-4. Adding a copper layer that is electrolytic in nature allows aluminum to carry a higher amount of current through the circuit created.

Layer of Insulation

The second layer is the insulation layer which is very important for creating a bond of insulation to support heat conductivity. The thermal conductivity of the aluminum PCB is dependent upon the insulating layer.

This layer is responsible for heat dissipation; the more spread of the insulation is to support the thermal conductivity, the more cooling of the component it will maintain to dissipate the heat.

The role played by the layer of insulation in the durability of a PCB, and the electronic component that will comprise this PCB is also essential. Hence, this needs to be very accurate.

Metal Substrate Layer

The final layer of the PCB amounts to the layer of the metal substrate. In the case of aluminum PCB, the required layer would be the aluminum substrate layer. The selection of metal depends on various factors, like the applications of the PCB.

However, aluminum proves to be the best choice when it comes to choosing metal substrates. This is because the cost-effectiveness and performance of the aluminum PCB make it a suitable option. There are many aluminum plates to choose from, some of which are 5052, 6061, 1060, and many more.

Applications of Aluminum PCB

Shenzhen PCB assembly manufacturers mostly prefer to opt for aluminum PCB assembling because of the various applications it justifies. Some of the applications of aluminum PCBs are as follows.

Relay Components

The solid-state relay components most need very efficient heat dissipation because they release heat. Hence choosing an aluminum PCB stack up could be a better idea for such components to keep them cool while they perform their function.

Consumer Electronics

Consumer electronics also contain the PCBs assembled within them, but since aluminum PCBs are economical and offer a lightweight finish, they are chosen for such electronic devices.

The portability factor is featured in the devices manufactured using aluminum PCBs; hence, various lighting fixtures used by consumers and camping gears comprise aluminum PCBs.

LED Based Components

Choosing LED components backed with aluminum PCBs is a very efficient idea because it controls the temperature of such devices and maintains their life, color, and brightness. Hence aluminum PCB for LED lighting and televisions are widely used.

Power Circuit Boards

High-power circuit boards need an efficient PCB that controls their temperature; hence, devices like AC-DC adapters and stabilizers comprise aluminum PCBs. The aluminum PCB keeps the temperature of these devices under control.

Musical Equipment

Various musical equipment also needs to keep their temperature under control; hence, they need aluminum PCBs within them. Equipment like preamps and mixers are equipped with such PCBs so that even if used for a more extended period, they do not heat up or stress the device.

Automobile

The use of aluminum PCBs is also quite popular in the automobile sector because of their ability to keep the devices cool. Since they are portable, they can easily be fixed and carried without causing much weight. Hence in the automobile sector, aluminum material PCB is used in ignition, power supply controller, and electronic regulator.

Computing Devices

Computing devices are also used for longer periods, so the load of power is also high. Therefore they also need a suitable PCB that helps them stay cool and away from heat. Therefore aluminum PCBs are widely used in most computing devices like CPUs, floppy drives, and power supply.

Elecrow: A Trustful Aluminum PCB manufacturer

As much as it is essential to choose the suitable PCB material, the significance of selecting the proper PCB manufacturer couldn't be denied. Elecrow PCB has proven to be one of the best China PCB assembly manufacturers offering the finest aluminum PCBs.

The best part is that you will have your choice of PCB manufactured, keeping the application of your PCB in line. We always consider the requirements of our clients, and after a thorough discussion and assessment of the PCB application, we develop aluminum PCBs for them.

We focus on quality, appropriate bonding within the PCB structure, and cost-effectiveness. Hence this allows us to provide our clients with a perfect PCB choice that lasts longer and keeps their devices cool irrespective of the heat released.