General introduction to IoT PCBA

The Internet of Things (IoT) has emerged as an exponentially expanding technology that revolutionizes our daily lives and professional environments.

IoT devices have become ubiquitous, permeating our homes, hospitals, industrial automation systems and wearables.

The Printed Circuit Board Assembly (PCBA) is at the heart of these IoT devices.

PCBAs serve as the fundamental infrastructure of IoT devices, facilitating essential connectivity and processing capabilities that drive their functionality.

In this blog post, we will delve into IoT PCBA, exploring its definition, understanding its immense importance and relevance in the modern world, and gaining insights into the topics covered in this discussion.

Understanding IoT PCBA

What is PCBA?

Think of a Printed Circuit Board Assembly, or PCBA for short, as the nerve center of electronic devices. It's like a complex roadmap that guides the flow of electricity, allowing components to communicate and work together seamlessly.

The PCB, a flat board made of non-conductive material, comes to life when it is populated with electronic components.

These components, such as microcontrollers, sensors, and communication modules, are precisely soldered onto the PCB, creating a network of interconnected pathways.

This assembly of components on the PCB is what we refer to as the Printed Circuit Board Assembly.

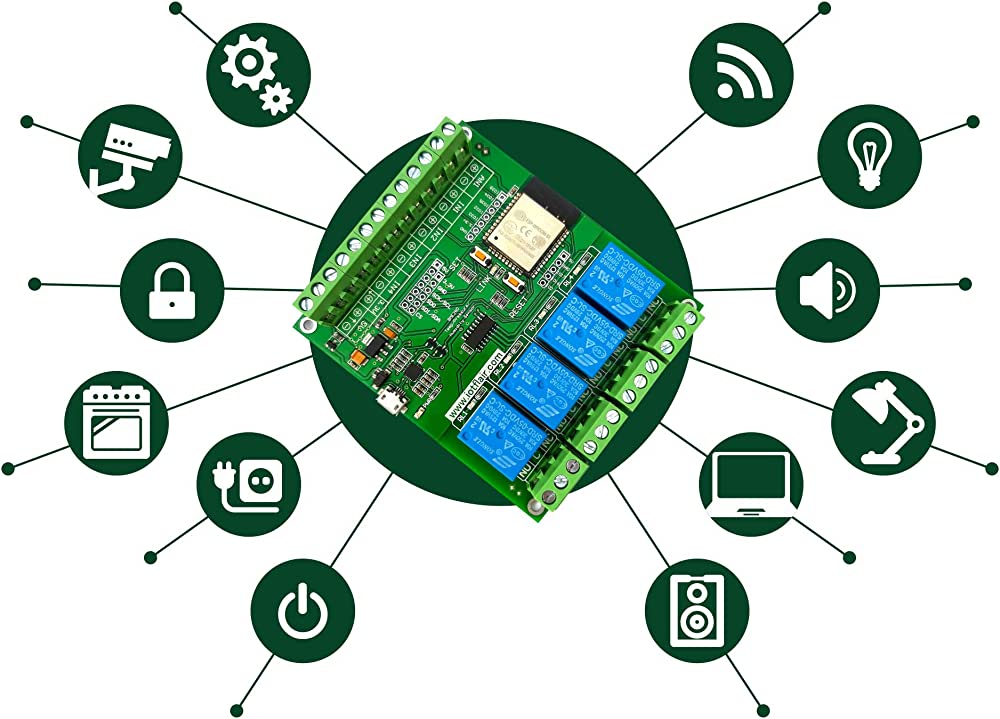

Role of PCBA in IoT devices

PCBAs are the unappreciated part of the Internet of Things. Without them, IoT devices would be mere shells without intelligence or functionality.

The PCBA provides the brains, senses, and communication capabilities that empower IoT devices to interact with the world around them.

In the context of IoT, PCBA acts as the central nervous system. It collects data from various sensors, processes it, and then communicates with other devices or the internet to take action based on the information received.

It's the key to unlocking the potential of IoT, enabling devices to adapt, learn, and make autonomous decisions.

Key components and their functions in IoT PCBA

Following are some of the essential IoT PCBA components and their general functions:

Microcontroller:

Microcontrollers can rightfully be referred to as the "brain" of the PCBA. These compact, integrated circuits house a processor, memory, and input/output peripherals, effectively serving as the control center of the IoT device.

They are responsible for executing instructions and managing the operations that drive the functionality of the device.

Sensors:

Sensors are essential as the "sensory organs" of the IoT PCBA, detecting and measuring physical quantities like temperature, humidity, motion, and light.

They convert these parameters into electrical signals, allowing the PCBA to interpret and analyze the data.

This collected data is invaluable, providing insights into the environment and forming the basis for informed decision-making and intelligent functionalities.

Communication modules:

They enable IoT devices to connect and share data with other devices or the internet. They can use various communication protocols like Wi-Fi, Bluetooth, Zigbee, LoRa IoT, or cellular networks to establish connectivity and facilitate seamless data exchange.

Power supply:

Power-supplying components ensure the IoT device receives a stable and reliable power source. They can include voltage regulators, batteries, or power management ICs, which optimize energy consumption and extend battery life.

Other supporting components:

In addition to the essential core components mentioned earlier, IoT PCBA may incorporate supplementary elements like memory chips, display modules, actuators, and more.

These additional components further enhance the device's functionality and facilitate user interaction.

Design Considerations for IoT PCBA

When designing an IoT PCBA, several crucial factors must be considered to ensure optimal performance, reliability, and functionality.

Let's delve into these design considerations, which shape the very foundation of an efficient and successful IoT device.

● Size and form factor

IoT devices are often integrated into compact and portable form factors, making size optimization a critical design consideration.

The PCB layout, component selection, and overall design should minimize the physical footprint while accommodating all necessary components and functionalities. This compactness enables seamless integration into various applications and enhances user experience.

● Power consumption and battery life

IoT devices often rely on limited power sources, such as batteries, necessitating careful power management. Designers must focus on optimizing power consumption to maximize battery life.

This can be achieved through efficient circuit design, low-power components, intelligent sleep modes, and power harvesting mechanisms.

Balancing functionality with energy efficiency is vital to creating IoT devices that can operate for extended periods without frequent battery replacements or recharging.

● Environmental factors and durability

IoT devices may encounter diverse environmental conditions, ranging from temperature variations to moisture, dust, and vibrations.

Designers must account for these factors to ensure the durability and reliability of the IoT PCBA.

Selecting components that can withstand harsh conditions, implementing appropriate protective measures like conformal coating or enclosure designs, and conducting thorough environmental testing are crucial in creating robust IoT devices.

● Security and data protection

As IoT devices become more interconnected, security and data protection becomes paramount.

Designers must incorporate robust security measures into the IoT PCBA to safeguard against potential threats.

This includes secure communication protocols, encryption algorithms, authentication mechanisms, and secure storage of sensitive data.

By prioritizing security from the design stage, IoT devices can help protect user privacy, prevent unauthorized access, and mitigate risks associated with data breaches.

● Cost and scalability

Designing IoT PCBA involves striking a balance between functionality, practicality and cost-effectiveness.

While incorporating advanced features and cutting-edge components may enhance the device's capabilities, it can also increase manufacturing costs.

Designers must carefully evaluate the trade-offs between performance and cost to ensure affordability and market competitiveness.

Additionally, scalability considerations are essential, as IoT devices may be produced in large quantities. Designing for scalability enables streamlined manufacturing processes and efficient production scaling without sacrificing quality.

Manufacturing and Assembly of IoT PCBA

Let's explore the critical aspects of manufacturing and assembling IoT PCBA.

● PCB design and layout considerations

The design of the PCB layout plays a crucial role in the of IoT device’s functionality and performance.

Designers carefully plan the arrangement of components, signal traces, and power planes to minimize noise, optimize signal integrity, and ensure efficient thermal management.

They consider factors like component placement, trace routing, and layer stack-up to achieve an optimal layout that meets the specific requirements of the IoT device.

Besides, they also ponder upon factors like IoT PCBA material, size, power and thermal management, and security to get the best out of IoT devices.

● Component selection and sourcing

Choosing the right components is vital for the success of IoT PCBA.

When selecting components, designers consider performance, reliability, compatibility, and cost factors. They ensure that the chosen components meet the IoT device's technical specifications and environmental requirements.

● PCB fabrication and assembly processes

The fabrication and assembly processes begin once the PCB design is finalized and components are sourced. It involves transferring the PCB design onto a physical board through etching, drilling, and copper plating.

Advanced manufacturing techniques, such as surface mount technology (SMT), are used for component placement and soldering. These techniques ensures precise and reliable connections between the components and the PCB.

● Quality control and testing procedures

Quality control is a critical aspect of IoT PCBA manufacturing. Rigorous testing procedures are employed to ensure the functionality and reliability of the assembled PCBs.

Automated optical inspection (AOI) and X-ray inspection detect defects or soldering issues.

Functional testing is done to ensure that the IoT device meets the desired performance criteria and functions as intended.

These quality control measures help identify and rectify any issues before the IoT PCBA reaches the market.

Examples and Applications of IoT PCBA

Here are some real-life examples and applications of IoT PCBA that showcase its versatility and impact on different aspects of our lives.

● Smart home automation systems

Imagine a home where lights, thermostats, security systems, and appliances seamlessly communicate, creating an intelligent and interconnected living environment.

IoT PCBA forms the backbone of smart home automation systems, enabling homeowners to remotely control and monitor their homes. From adjusting lighting and temperature settings to receiving real-time security alerts, IoT PCBA facilitates a convenient and secure living experience.

● Industrial IoT solutions

IoT PCBA has revolutionized industrial processes, paving the way for Industry 4.0.

IoT PCBA enables real-time monitoring and control of machinery by integrating sensors, actuators, and communication modules and optimizing efficiency, productivity, and predictive maintenance.

Industrial IoT solutions powered by IoT PCBA have transformed manufacturing, logistics, and supply chain operations, improving operational efficiency and cost savings.

● Healthcare monitoring devices

IoT PCBA plays a crucial role in healthcare by enabling remote patient monitoring and personalized healthcare solutions.

From wearable devices that track vital signs and physical activity to smart medication dispensers that ensure medication adherence, IoT PCBA empowers healthcare providers with real-time patient data, leading to better diagnostics, timely interventions, and improved patient outcomes.

These examples merely scratch the surface of the vast possibilities offered by IoT PCBA.

IoT PCBA is revolutionizing industries and improving our quality of life, from smart cities to transportation, from energy management to retail.

Conclusion

IoT PCBA plays a pivotal role in shaping the future of technology and its integration into our daily lives. From smart homes to industrial applications, healthcare to environmental monitoring, IoT PCBA enables a new level of connectivity, intelligence, and efficiency.

Elecrow, a leading provider of IoT PCBA solutions, understands the significance of sensors in the Internet of Things ecosystem.

They offer a wide array of high-quality sensors crucial to IoT PCBA. These sensors enable devices to gather real-time data, monitor environmental conditions, detect motion, measure physical quantities, and much more.

By integrating Elecrow's sensors into your IoT projects, you can enhance the capabilities and functionality of your devices.

Request IoT PCBA Instant Quote