Getting Your Custom PCBs Made Right From Concept to Circuit

In the electronics world, the Printed Circuit Board (PCB) is the quiet foundation holding everything together. Whether you're a startup founder chasing a breakthrough, an engineer fine-tuning a product, or a hobbyist bringing a cool idea to life, turning that digital schematic into a real, working circuit board is a make-or-break process. Let's walk through the essentials: why making PCB prototypes first is crucial, how to pick a good PCB manufacturer, and what's involved when you actually order PCBs.

Why Prototyping First is a Smart Move

Before you even think about a big production run, building PCB prototypes is a step you really shouldn't skip. Think of a prototype pcb as your reality check. It lets you test if your design actually works, spot potential headaches (like components not fitting!), and tweak things easily before it gets expensive. Jumping straight to mass production without this stage? That's often a recipe for costly mistakes, delays, and maybe even a product that doesn't work.

Here’s why building test boards early pays off:

- Catch Glitches Early: Finding design flaws or connection problems at this stage saves a ton of time and money compared to fixing them later.

- Test How It Works: Does the circuit actually do what you designed it to do under real conditions? Prototypes tell you.

- Design, Test, Repeat: Prototypes make it easy to try out changes quickly. Fine-tune your custom pcb design until it's just right.

- Save Cash: Fixing issues on a few prototype boards is far cheaper than scrapping a whole production batch.

- Show, Don't Just Tell: A working prototype is powerful proof your idea is solid, especially if you need funding or buy-in.

When looking for a pcb prototype service, think about how fast you need the boards (quick-turn options are common), what materials you need (standard FR-4 is typical, but maybe you need something special?), how many layers, and how fine the details (trace/space) need to be. Many places specialize in pcb prototypes and have simple processes for these small orders.

Choosing Your PCB Fab House: Finding the Right Partner

Okay, your PCB prototype works! Now you need someone to make the final custom PCBs. Picking the right PCB manufacturer (often called a fab house) is important. There are tons of pcb makers out there, from quick prototype shops to giant factories. Who you choose affects the quality, cost, and how quickly you get your boards.

PCB manufacturer quality control

Here's what to weigh up when picking a supplier:

- Can They Actually Make Your Board?

- Complexity: Check if they can handle your layer count, the tiny details (trace/space), any special vias (holes connecting layers), or advanced stuff like HDI or flexible boards.

- Materials: Do they have the exact materials (laminates, copper thickness) your design specifies?

- Finishes: What surface finishes do they offer (like HASL, ENIG, OSP)? Which one suits your components and assembly process best?

- How's Their Quality Control?

- Look for proof of quality, like ISO 9001 certification. UL listing is good for safety. Specific industry certs (aerospace, medical) matter if that's your field.

- Ask how they check boards – do they use automated optical inspection (AOI), X-rays for complex parts, and electrical testing (flying probe or bed-of-nails) to catch defects?

- How Fast Can You Get Boards?

- What are their standard delivery times? Can they rush orders if needed? Are they reliable with their deadlines?

- What's the Real Cost?

- Get quotes! Understand the price per board, but also ask about setup fees (NRE), shipping, and if there's a minimum number of boards you have to order (MOQ). Compare quotes from a few places.

- Can You Get Help When Needed?

- Good customer service and easy-to-reach tech support are gold. A good partner will often offer a Design for Manufacturability (DFM) check – basically, they review your files and suggest tweaks to make the board easier (and maybe cheaper) to build reliably.

- What's Their Reputation?

- Do some digging. Look for reviews, ask around in online forums, or see if they have case studies from companies like yours.

Often, the same company can handle both your pcb prototype service needs and larger production runs, which can simplify things. But sometimes, the best place for super-fast, cheap prototypes isn't the best fit for a high-volume, high-complexity job.

Online PCB order interface

Placing Your PCB Order: Files, Specs, and Checks

Ordering PCBs online is pretty common now, but you need to get your design files ready carefully to make sure the pcb printing and building process goes smoothly.

Here’s the typical flow:

- Get Your Files Ready (Gerber Files):

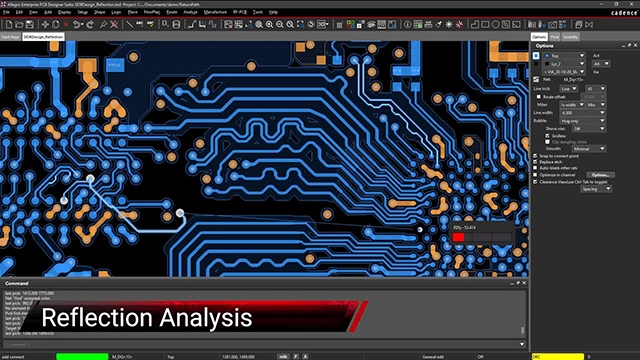

- The standard language factories understand is Gerber files (usually RS-274X format). Your PCB design software (like Altium, Eagle, KiCad) creates these.

- You'll need files for each copper layer, solder mask, silkscreen (the text/labels), drill holes (usually an Excellon file), and the board outline.

- Pro Tip: Always double-check your generated Gerbers with a separate viewer program before sending them off. It catches many simple mistakes!

- Get Quotes and Place the Order Online:

- Most PCB manufacturers have a website where you upload your Gerbers and enter specs to get a price, often instantly.

- You'll need to specify things like:

- Board size

- How many you need

- Number of layers

- Material (FR-4 is common) & thickness

- Copper thickness (1oz is standard)

- Surface finish

- Solder mask & silkscreen colors

- Any special needs (like impedance control).

- The DFM Check:

- A good manufacturer will run a Design for Manufacturability (DFM) check on your files. This spots potential problems for their equipment (like traces too close together, missing drill info). Fixing these issues upfront avoids delays and bad boards.

- Confirm and Pay:

- Once the quote looks good and any DFM issues are sorted, you confirm the order pcb details and pay up.

- Wait for Your Boards!

- The factory then does its magic: imaging, etching, drilling, plating, applying masks and text, finishing, and testing.

- You should get tracking info when they ship.

Seriously, double-check everything before you hit that final submit button on your pcb order. A small mistake in the specs can mean getting a batch of expensive coasters.

Custom PCBs ready for order fulfillment

Wrapping Up: Turning Ideas into Working Circuits

Getting from an idea to a working custom pcb takes attention to detail. But by taking PCB prototyping seriously, choosing your PCB manufacturer wisely, and being careful when you place your PCB order, you set yourself up for success. These steps might seem like a lot, but they're key to getting reliable, quality boards made efficiently, whether it's for your next big product or just a fun personal project.