A Complete Guide to Drilling in PCB Manufacturing (2025)

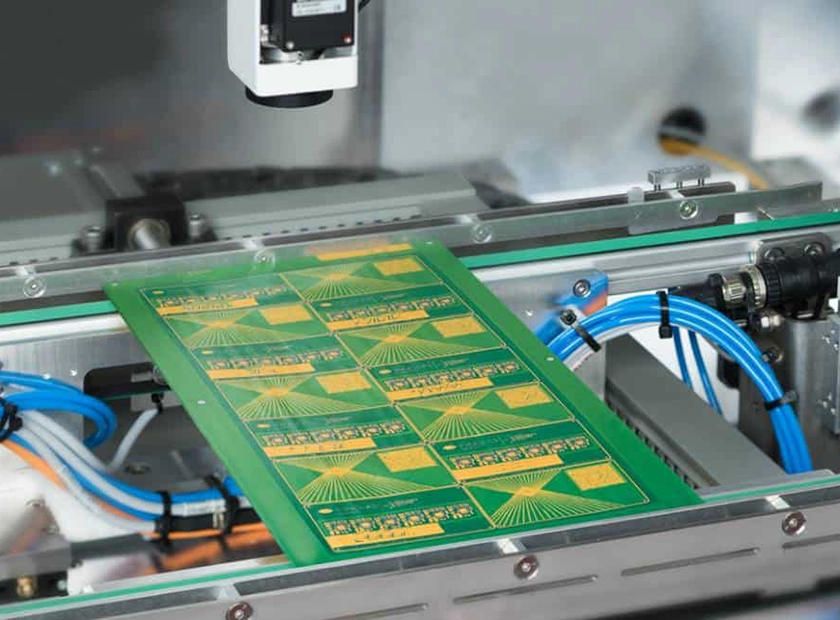

The Foundation of Modern Electronics

In the intricate world of electronics, a successful pcb assembly depends on the quality of every preceding step. While our expertise lies in the final assembly, we know that no component can function without the foundational network created by the drilling process during board fabrication. Drilling is far more than simply creating holes; it's the critical enabler of electrical interconnection. This guide explores the drilling process to help you understand what defines a high-quality foundation for any electronics project, ensuring a smooth transition to manufacturing and final assembly.

The Indispensable Role of Drilling in Fabrication

The importance of drilling stems from its dual contributions to the final board's functionality. First, it creates the vias that facilitate electrical connections between layers. Second, it provides mechanical support for through-hole components. The vias, once drilled, are transformed into conductive pathways through a plating process. For through-hole components, the drilled holes provide a secure anchor. Component leads are inserted and soldered during the pcb assembly stage, creating a robust physical and electrical bond that relies entirely on the precision of the initial drilling.

PCB Drilling Process

Mechanical Drilling: The Workhorse of the Industry

Mechanical drilling remains the foundational method for creating through-holes in the vast majority of projects. For a successful pcb assembly, the quality of these mechanically drilled holes is paramount, as they directly impact component mounting and solder joint integrity.

- Precise Control of Parameters: Achieving a clean and accurate hole depends on the optimization of several key process parameters, including:

- Spindle Speed: The rotational speed of the drill bit.

- Feed Rate: The speed at which the drill bit advances into the PCB.

- Retract Rate: The speed at which the drill bit is withdrawn.

- Limitations: While cost-effective for standard holes (≥0.2mm), mechanical drilling reaches its physical limits when dealing with very small holes or those with a high aspect ratio. Physical stress can also be a concern for thin or exotic materials.

Laser Drilling: The Microvia Revolution

For High-Density Interconnect (HDI) boards, where space is at an absolute premium, laser drilling becomes essential. It utilizes a focused beam of high-energy light to ablate material, creating microvias that are crucial for modern, complex designs destined for advanced pcb assembly.

- Ablation Methods: Lasers achieve ablation through either photothermal or photochemical processes. The latter, common with UV (ultraviolet) lasers, is a "cold" process that minimizes thermal stress.

- Laser Types & Applications: CO2 lasers excel at ablating dielectric materials. UV lasers, however, provide superior precision for the smallest and cleanest microvias, which is why leading manufacturers like a few manufacturers can reliably produce laser-drilled holes as small as 0.1mm.

Advanced Via Structures & Design Flexibility

The ability to create complex via structures is a cornerstone of modern electronics design. These advancements enable denser component placement and more complex routing. Ultimately, this design flexibility directly impacts the final pcb assembly stage, allowing for more compact and powerful products.

- Blind Vias: Connect an outer layer to one or more inner layers.

- Buried Vias: Exist entirely between inner layers.

- Stacked and Staggered Microvias: Optimize vertical connections for high-density routing.

These advanced structures are crucial for maximizing routing density. When selecting a fabrication partner, ensure they explicitly support blind and buried vias for your advanced projects.

PCB Prototype Making

Quality Assurance: Avoiding Pitfalls in Fabrication

A flawless assembly is impossible without a robust quality assurance program at the board fabrication stage. Each step in the pcb manufacturing journey, especially drilling, introduces potential for defects. Understanding and mitigating these risks is a necessity for producing reliable electronics. Key defects and mitigation strategies include:

- Resin Smear: The primary risk, which can be managed through chemical or plasma desmear processes.

- Nail Heading: Addressed through careful selection of drill bits and parameters.

- Burring: Removal of sharp copper edges through a deburring process.

- Hole Wall Roughness: Ensuring uniform plating is critical to prevent stress concentrations.

Post-drilling cleaning and preparation are as important as the drilling itself.

How Fabrication Quality Impacts Your Assembly Partner

Choosing the right partners across the entire pcb manufacturing chain is crucial. While your pcb assembly provider may not perform the drilling, their success is directly tied to its quality. Consider the following factors when evaluating a fabrication house:

- Technical Prowess: Can their equipment achieve your required minimum hole size and support the necessary via types? This directly impacts the success of the final assembly.

- Process Transparency: Do they provide detailed information about their drilling and quality control processes?

- Quality Systems: What are their quality assurance procedures for drilling, desmear, and plating?