Back to School with STEM-Limited-Time Event(Aug 6-Sep 5)

In today's highly automated electronics manufacturing, PCB assembly seems dominated by machine precision. However, for top-tier quality and complex solutions, an undeniable truth emerges: human intelligence, experience, and craftsmanship are the backbone of the process.

This human element is not just a supplement; it is a core factor determining a product's success. Leading assembly houses, including professional providers like Elecrow, understand this deeply, making manual intervention a key part of their quality assurance.

Superior manufacturing starts with strict control over raw materials. During Incoming Quality Control (IQC), the human role is immediately evident.

Experienced inspectors use their senses to identify subtle defects that machines might miss. These include:

This experience-based judgment acts as the first filter against supply chain risks.

Even after automated SMT processes, a manual visual inspection is critical. Technicians use high-magnification tools to check for "grey areas" that Automated Optical Inspection (AOI) might overlook, such as solder wetting under BGAs or micro-fine solder bridging. This ensures the soldering quality approaches perfection.

Manual vs. Automated PCB Assembly Techniques

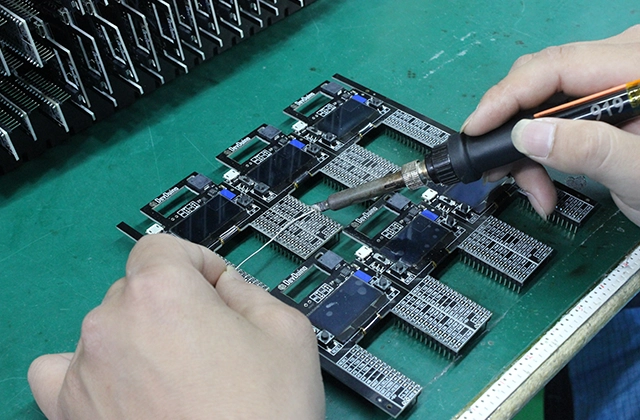

While SMT is mainstream, Through-Hole Technology (THT) components are still vital for high-reliability applications like power supplies and aerospace. Assembling large connectors or power devices often requires manual soldering.

At companies like Elecrow, a skilled manual soldering team is a core competency. These technicians meticulously control temperature and solder application, ensuring each joint is robust without causing thermal damage. For odd-form components, human flexibility is unparalleled.

Expert manual rework and repair skills are also a "lifesaver" during prototyping or when minor defects occur. This is especially true for High-Mix, Low-Volume (HMLV) production models, where manual operations offer unmatched flexibility and cost-effectiveness.

Consider a PCBA for a precision medical device. An AOI scan might show no errors, but an experienced inspector could spot the early signs of "tombstoning" on a tiny capacitor—a long-term reliability risk. The manual soldering of a thermally sensitive optical sensor is another area where human skill prevents damage.

In another case, an industrial controller prototype has a signal interference issue. Instead of a costly redesign, an experienced engineering team from a provider like Elecrow can make precise manual adjustments to the board, fixing the problem and keeping the project on schedule.

Checking and repairing a PCB manually

The superior quality of modern PCB assembly comes from a profound synergy between humans and machines. From material control to the precision assembly of special components, manual inspection and soldering play an indispensable role.

Valuing this "human element" is key for any enterprise committed to high-quality PCB assembly to maintain a competitive edge. It is the foundation for reliability, value, and innovation.