The Top 6 strongest 3D printer filaments in 2023

The Top 6 strongest 3D printer filaments in 2023

3D printing is a fantastic technology that can make your ideas come to a real-life project just by simple steps, however, the 3d printer filament like PLA sometimes cannot build sturdy objects to fulfill high-demand electronics project needs.

To increase the strength and durability of 3D printed parts, it's recommended to use strong filaments instead of normal filaments. In this blog we will explore the concept of filament strength and highlight 6 of the strongest 3D printer filament types available for end-use parts 3D printing.

The Strength standards

Tensile Strength

Tensile strength is a measure of a material's ability to resist deformation when stretched; a high tensile strength indicates that a material can withstand a great deal of stress before breaking. 3D printer filaments such as PEEK, polycarbonate, and carbon fiber-infused filaments have high tensile strengths, making them the strongest 3D printer filaments for load-bearing applications due to their high tensile strength.

Impact resistance

Impact strength is the ability of a material to withstand sudden stress without cracking or breaking. 3D printer filaments such as polycarbonate, nylon, and PEEK perform exceptionally well in this category and can withstand high impact loads without cracking, making them popular choices for tool housings, safety boxes, eyewear, and safety equipment.

Chemical resistance

Chemical fluids and harsh environments can severely impact the performance of certain materials, making chemical resistance a critical factor for applications that involve such conditions. When it comes to 3D printing objects that will be exposed to harsh chemicals, the strongest 3D printer filaments, such as nylon and polycarbonate, offer excellent chemical resistance, making them highly durable even in harsh chemical environments. ABS is also one of the strongest filaments and offers great chemical resistance, but makers should know that it falls short of the rugged resistance of nylon and polycarbonate.

UV resistance

For outdoor applications, it's important to use a 3D printing filament that can withstand the damaging effects of UV exposure from sunlight. Constant exposure to UV radiation can weaken the material's bonds, potentially causing the printed parts to fail. To ensure the durability and reliability of your outdoor 3D printed parts, it's best to choose filaments with high UV resistance. ABS, ASA, and nylon are among the most durable and strongest 3D printer filaments that offer superior UV resistance, making them ideal for functional outdoor applications.

Temperature resistance

When working on DIY electronics projects with higher temperature requirements, it's important to use 3D printing filaments that can withstand extreme temperatures without softening, warping, or failing, which can negatively affect the finished projects. The 3D printer filaments with high heat resistance are able to perform better under such harsh conditions.

The strongest 3D printer filaments, such as nylon, PEEK, and polycarbonate filaments, perform well in high-temperature applications, but they require higher printing temperatures than other filaments. Therefore, it's recommended to use the hot end that can withstand high temperatures when printing these materials.

What are the strongest 3D printer filaments?

Polycarbonate

Polycarbonate (PC), one of the strongest filaments with transparent and lightweight properties, has excellent impact strength, toughness, and temperature resistance. In 2020, a study found out that the polycarbonate filament has a tensile strength exceeding 5200 PSI, making it one of the strongest 3D printer filaments in the 3D printer filament market today.

Polycarbonate filament is also highly resistant to chemicals and UV rays. In addition, it can be heated to 140°C before softening and is even used as an additive to greatly improve the properties of ABS filament. With these properties, they can be used to print medical instruments, protective equipment, and functional prototypes.

The disadvantages of PC filament are also quite obvious, due to its difficult printing properties, warping ability, and tendency to absorb moisture, it can sometimes be tricky to print, you need an enclosed 3D printing machine and proper filament storage box to ensure the smooth printing of the finicky PC filament.

After successfully overcoming these challenges, polycarbonate will be the strongest 3D printer filament for durability and high-temperature applications.

PC filament

Dry Hygroscopic filament in a food dehydrator (Notes: the filament shown in the picture is normal PLA filament)

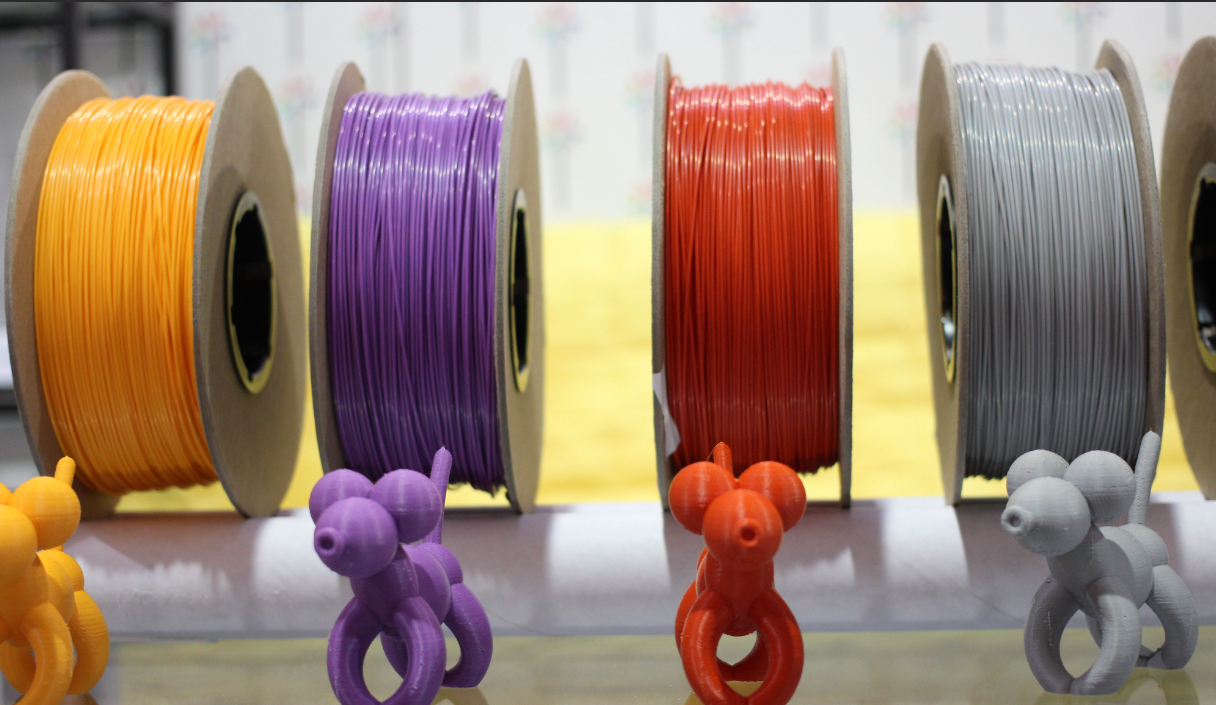

Nylon

According to various tests, a hook printed with nylon filament can withstand a tensile strength of up to 7,000 PSI, which is significantly higher than the 4,700 PSI of ABS. In addition, a clip printed with nylon filament was found to hold an impressive 485 pounds.

Several brands of nylon filament have been tested in previous research, and it's said that nylon filaments of different brands have some similar results. MatterHackers found that their NylonX filament had an average hook strength of 364 pounds before breaking, while Rigid.Ink rated some nylon filaments four out of five for strength and five out of five for durability, which are pretty convincing tests suggesting that nylon is quite robust.

However, the downside of printing with nylon filament can be a bit more challenging than with other filaments. It's hygroscopic and tends to warp easily, and requires a higher print temperature of 220-270°C. Nylon absorbs moisture from the air and must be kept dry. However, it is highly resistant to impact, fatigue, and heat. Successful nylon printing also requires a precisely controlled printing environment.

Overall, nylon filament is a reliable option for printing strong and durable items, especially those that require resistance to harsh conditions. It is undoubtedly one of the strongest 3D printer filaments with high strength and durability, making it a popular choice among 3D printing enthusiasts despite its slightly more demanding printing requirements.

ABS

ABS (acrylonitrile butadiene styrene) filament is one of the earliest and still widely used thermoplastics for 3D printing due to its low cost and versatility. However, PETG and ASA filaments are increasingly preferred due to their superior properties.

A 2019 study found that ABS is stronger than polycarbonate filament, with an ultimate tensile strength of more than 4500 PSI. This makes ABS a better choice for printing due to its relative ease of printing and accessibility.

ABS has a high melting temperature and is suitable for functional prototypes, automotive components and aesthetic models. It can be post-processed with acetone for a smooth surface finish. Warping can be an issue, but printing inside an enclosure helps contain fumes and improve results.

As one of the strongest 3D printer filaments, ABS is ideal for applications with higher temperatures, such as cars in direct sunlight.

TPU

The flexible polyurethane filament, called TPU (thermoplastic polyurethane), can be formulated by manufacturers to provide high stiffness or high elasticity, depending on the materials mixed together.

After testing several brands of TPU filament, Devin from Make Anything found that TPU filament is very durable and can withstand high loads before breaking. TPU's resistance to abrasion and chemicals makes it suitable for printing protective gear, phone cases, prosthetics, and even footwear. TPU can be printed at lower temperatures and doesn't require high-end 3D printers. However, due to its flexible nature, it can be difficult to 3D print with Bowden extruders and should be printed at slower speeds to avoid hot-end jams. In addition, adjusting the infill value can affect the stiffness of TPU parts.

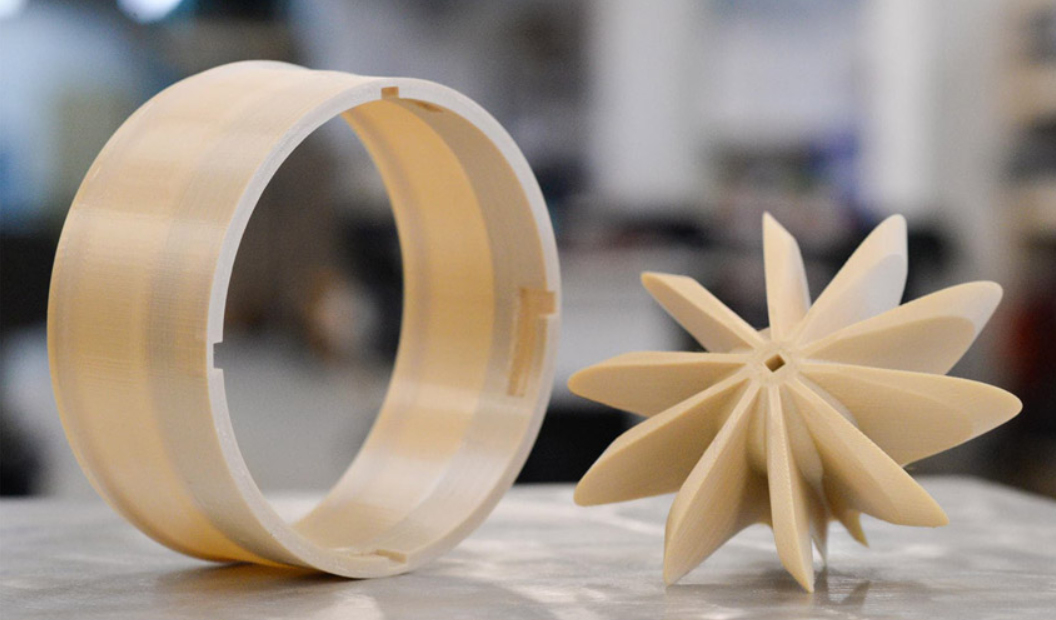

PEEK

PEEK (PolyetherEtherKetone) is a high performance thermoplastic and the strongest 3D printer filament with a tensile strength of approximately 7250 PSI. Its excellent strength-to-weight ratio with a Young's modulus similar to human bone allows it to be used in medical applications. Its light weight and high temperature resistance also make it suitable for aerospace applications. PEEK is expensive, requires a special 3D printing setup, and is mostly used for industrial applications, but it can be successfully printed at home with the right equipment and setup.

Carbon Fiber

Carbon fiber is commonly used to reinforce various 3D printer filaments such as PLA, polycarbonate, PETG and nylon. The resulting material has short carbon fibers embedded in the filament, providing increased hardness and abrasion resistance. Parts printed with carbon fiber filament are lighter and stiffer than those printed with regular filament.

Carbon-fiber-infused nylon filaments are particularly hard, making them suitable for machine parts and structural components such as 3D printed drone frames, tools, and support structures. However, their tensile strength remains similar to that of regular nylon filament. The use of stainless steel or ruby-tipped nozzles is recommended when printing with carbon fiber due to its high hardness, as regular bronze nozzles can wear out quickly. In addition, printing at low speeds can reduce clogging and ensure consistent print quality.

Final Words

As an expertise in PCB manufacturing, PCB assembly, 3D printing services, component sourcing, Elecrow is glad to provide makers or other customers any 3D printing services they want, Elecrow is glad to include you in the 3D printing field and help you 3D print your projects beautifully. Elecrow even start a partner seller program for makers to bring their creative ideas to life, join our partner seller program to mass produce your ideas to solid projects and earn your profits here!

______________________________________________________________

Btw, Raspberry Pi boards are popular and versatile tools for makers. The latest addition to the lineup, Raspberry Pi 5, is the most powerful version yet. Why not upgrade your projects with this cutting-edge device? Join our Giveaway campaign for Elecrow fans to win a brand new Raspberry Pi 5. Don't miss out! Good luck!

Elecrow Monthly RaspberryPi 5 Giveaway