PCBA Prototyping Manufacturing Process: From Design to Functionality

PCBA Prototyping Manufacturing Process: From Design to Functionality

Printed Circuit Board Assembly (PCBA) is the foundation of modern electronic products. Before entering mass production, creating a PCB assembly prototype is a critical step that helps validate your design, test real-world performance, and minimize costly mistakes. Whether you're a startup building a proof of concept or an engineer refining a new product, PCBA prototyping sets the stage for successful manufacturing.

What Is PCBA Prototyping?

PCBA prototyping is the process of building a small batch of functional circuit board assemblies based on your electronic design. These boards are fully assembled with components and soldered connections, allowing engineers and developers to:

● Test and validate circuit performance

● Identify and correct design issues

● Evaluate manufacturability and PCB assembly requirements

● Ensure compatibility with enclosures and external systems

Unlike full-scale production, prototyping is about agility and learning. Typical runs range from one to a few dozen boards, giving room for iterative improvements.

Key Steps in the PCBA Prototyping Process

1. Design & File Preparation

Everything begins with your circuit design. Engineers use EDA (Electronic Design Automation) tools like Altium, KiCad, or Eagle to design the schematic and PCB layout. Once the design is finalized, the following files must be prepared:

● Gerber files for PCB fabrication

● BOM (Bill of Materials) listing each component, part number, and specifications

● CPL (Component Placement List) detailing where each component should be placed on the board

Before moving forward, it's essential to conduct a Design for Manufacturability (DFM) review to catch any potential issues that could affect production or PCB assembly.

2. Component Sourcing

Next, all the parts listed in the BOM are sourced. For prototypes, speed and availability are key. It’s common to replace out-of-stock parts with similar alternatives to avoid delays. Elecrow also provides component sourcing services, so you can save your efforts by letting us handle the procurement of high-quality parts for your projects.

3. PCB Fabrication

Your PCB is fabricated using the Gerber files. Prototypes usually use 1 to 4 layers, FR4 material, and standard finishes like HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold). Elecrow Quick-turn PCB services often deliver in just a few days.

4. Solder Paste Application

The PCB assembly process begins by applying solder paste to the board's pads before placing components. This is typically done using a stencil printer to ensure precision, although jet printing may be used for small batches.

5. Pick and Place

Automated pick-and-place machines carefully position each surface-mount component (SMD) onto the board based on the CPL file. Through-hole components may be manually placed, especially in prototype PCB assembly runs.

6. Reflow Soldering / Wave Soldering

For SMDs, the board goes through a reflow oven where the solder paste melts and secures the components in place. If through-hole components are used, wave soldering or manual soldering is performed.

7. Inspection & Testing

Once the PCB assembly is complete, the prototype undergoes a thorough inspection:

● Visual inspection for solder joints and alignment

● AOI (Automated Optical Inspection) for detecting defects

● X-ray inspection for hidden joints (e.g., BGAs)

● Basic functional tests to ensure power-up, signal integrity, and system behavior. To further ensure the functionality of your boards, Elecrow offers FREE PCBA functional testing for our customers

Common Challenges in PCBA Prototyping

● Component shortages: Some parts may have long lead times or be obsolete

● Design errors: Issues like trace interference, incorrect footprints, or thermal problems often appear in the prototype stage

● Assembly errors: Misaligned components or reversed polarity can happen without proper file checks

Tips for a Successful PCBA Prototype Run

● Use clear and complete documentation (BOM, CPL, Gerber)

● Start with a small quantity to test design assumptions

● Select a PCBA partner who provides feedback, testing, and fast iterations

● Communicate expectations clearly, including testing protocols and deadlines

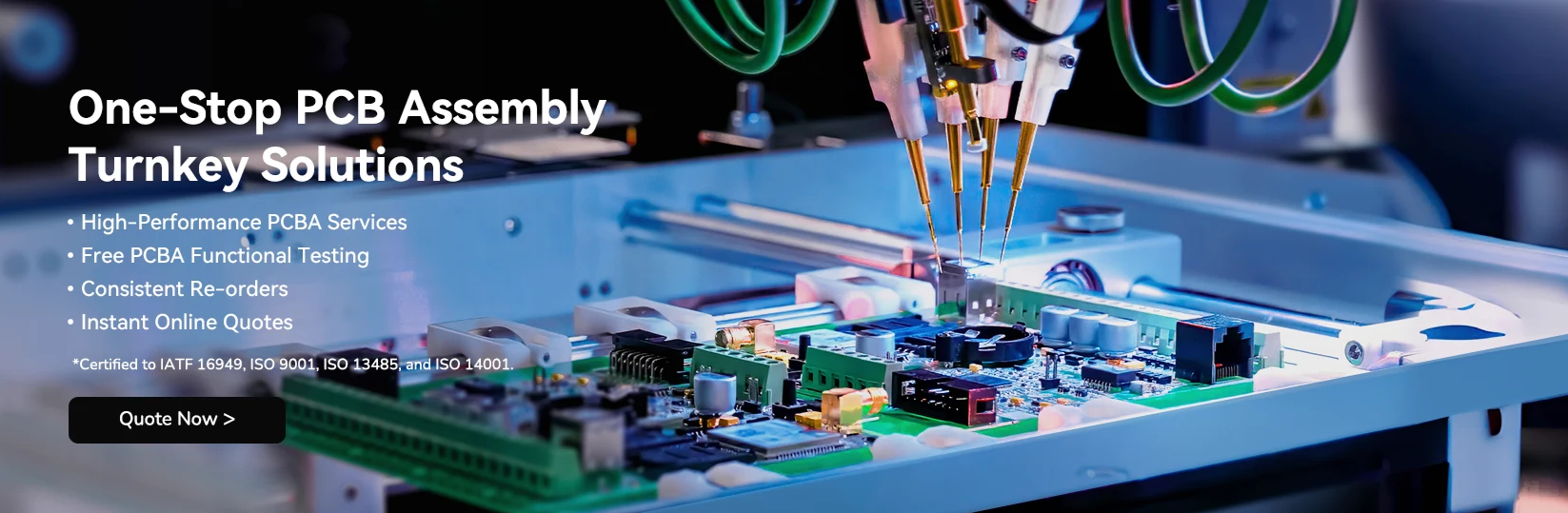

Why Choose Elecrow for PCBA Prototyping?

Elecrow offers a one-stop PCB assembly prototyping service, combining fast PCB manufacturing and expert assembly techniques. Our advantages:

● In-house fabrication and assembly streamline the workflow

● Free Functional Testing to ensure your boards work flawlessly

● Certified Quality: ISO 9001, ISO 13485, ISO14001, and IATF 16949 standards ensure consistent performance

● Engineering support for design reviews and feedback

PCBA prototyping is your gateway to building reliable, scalable electronic products. It helps verify performance, improve designs, and reduce risks before committing to full production. Whether you're developing wearables, IoT devices, or industrial controllers, starting with a robust prototype is the smartest way forward.

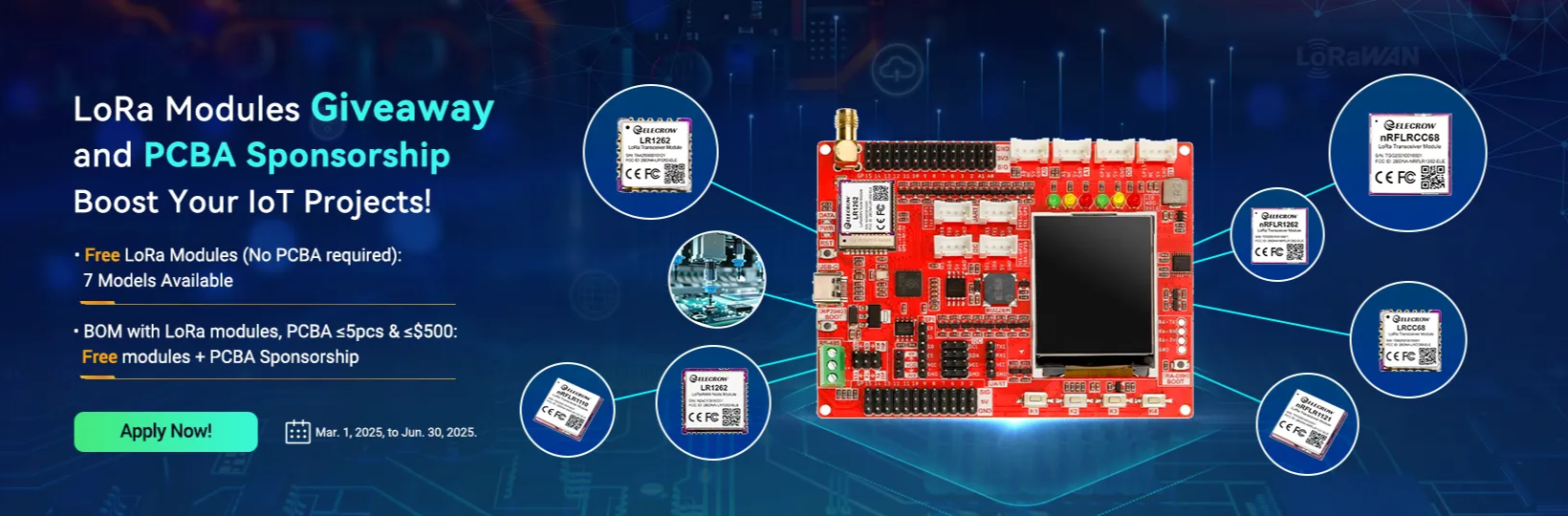

BTW, the Elecrow LoRa Modules Giveaway and PCB Assembly Sponsorship are in full swing! If your project involves LoRa modules, don’t miss the chance to bring it to life at no cost—apply for Elecrow’s PCB Assembly Sponsorship and LoRa Modules today.

Ready to bring your idea to life? Get an instant online quote