Currency

Elecrow 3D Printing - One-click order to get 10% limited discount

March 11, 2022

3D printing is a kind of rapid prototyping technology which based on digital model files, using powder metal or plastic and other adhesive materials to construct objects by printing layer by layer. 3D printing is usually realized by using digital technology and material printer, It is often used in mold manufacturing and industrial design. It has been gradually used in the direct manufacturing of some products, and there are already parts printed with this technology. The technology has applications in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, GIS, civil engineering, firearms and other fields.

(At the same time, we will give you 10% discount on 3D printing orders, the promo code is 7PALL6AU2131, limited quantity first come first served ~)

Principle of 3D printing technology

1. 3D design

The design process of 3D printing is: At first ,use CAD or computer animation modeling software to design model, and then "divide" the built three-dimensional model into layer by layer sections, so as to guide the printer to print layer by layer. The standard file format between design software and printer is STL format. An STL file uses triangular surfaces to roughly simulate the surface of an object. The smaller the triangle, the higher the resolution of the generated surface. Ply is a scanner that generates 3D files by scanning. The generated VRML or WRL files are often used as input files for full-color printing.

2. Printing process

The printer reads the cross-section information in the file, prints these cross-sections layer by layer with liquid, powder or sheet materials, and then binds the cross-sections of each layer in various ways to create a solid. The characteristic of this technology is that its collection can make objects of any shape.

Traditional manufacturing technologies, such as home plastic method, can produce a large number of polymer products at a lower cost, while 3D printing technology can produce a relatively small number of products in a faster, more flexible and lower cost way. A desktop size 3D printer can meet the needs of designers or concept development teams to make models.

3. Completion

At present, the resolution of 3D printer is enough for most applications (the curved surface may be rough, like sawtooth on the image). You can use the following methods to obtain higher resolution items : first use the current 3D printer to make a slightly larger object, and then slightly polish the surface to obtain smooth "high-resolution" items.

Types of 3D printing technology

1. SLA( Stereolithography Apparatus )

This is one of the earliest commercial 3D printing technologies and one of the most common technologies. The liquid photosensitive resin is polymerized by UV irradiation to solidify layer by layer and generate three-dimensional solid. Because the raw material is liquid, the support needs to be set during printing, and then manually remove the support after printing.

2. SLS(Selective laser Sintering)

This is an industrial 3D printing technology, which uses powder materials such as nylon to make accurate and durable parts. Similar to other 3D printing technologies, the infrared laser beam is selectively sintered according to the layered section information under the control of the computer. After one layer is completed, the next layer is sintered. After all sintering, the excess powder is removed, and a sintered part can be obtained.

3. FDM( Fused Deposition Modeling )

This is a common 3D printing technology and one of the most common technologies. FDM makes parts by extruding plastic filament materials through nozzles and stacking them layer by layer in the workbench. FDM can realize simple high-precision printing of parts, but due to the limitation of technology, any overhang features need support materials and need to be removed after printing. Therefore, the precision of more complex parts with suspended structure will be slightly worse.

4. MJF(Multi-Jet Fusion)

This technology mainly uses two separate thermal inkjet arrays to produce parts. During printing, one of them will spray flux and the other will spray fine agent to apply energy to the forming area to melt the powder. These steps will cycle back and forth until the whole object is printed in layers. MJF can process nylon materials with better mechanical properties, and MJF can achieve shorter processing cycle because it does not need pre heating and cooling.

5. SLM(Selective laser melting)

It is an industrial grade metal 3D printing technology. By sintering metal powders together, a series of metal materials are made into parts one layer at a time. This process can create highly complex shapes, which is almost impossible to achieve through other traditional machining methods.

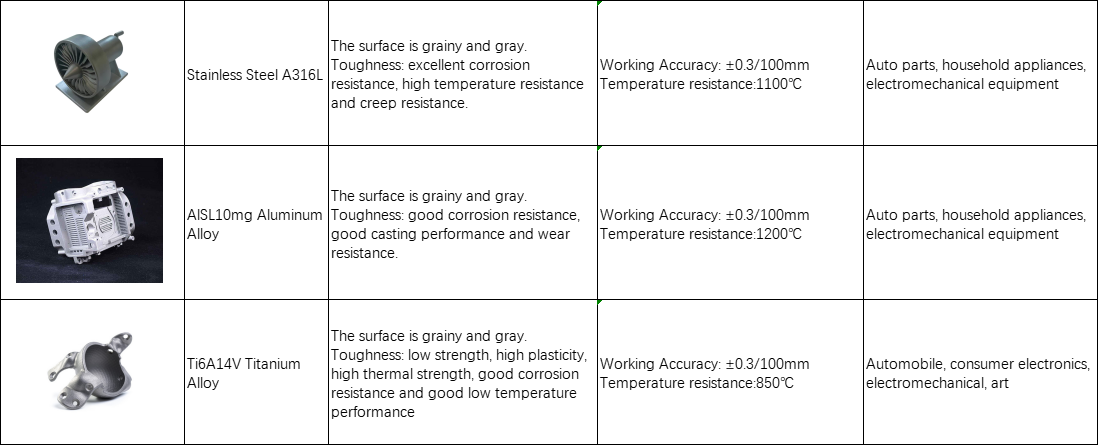

3D printing materials