The Magic of Laser Cutting Acrylic for Sharp Designs and Flawless Finishes

Ever wondered how those intricate acrylic designs come to life with such flawless edges? The secret often lies in laser cutting technology, a game-changer that's completely reshaped the world of acrylic creation. Moving far beyond traditional methods, laser cutting brings a host of benefits to the table: think incredible precision, design freedom, and impressive speed. This makes it the go-to choice for a vast array of creative projects. Whether you're dreaming up complex artwork, crafting eye-catching signage, or developing unique architectural elements, laser cutting opens up a universe of innovation and custom-tailored possibilities.

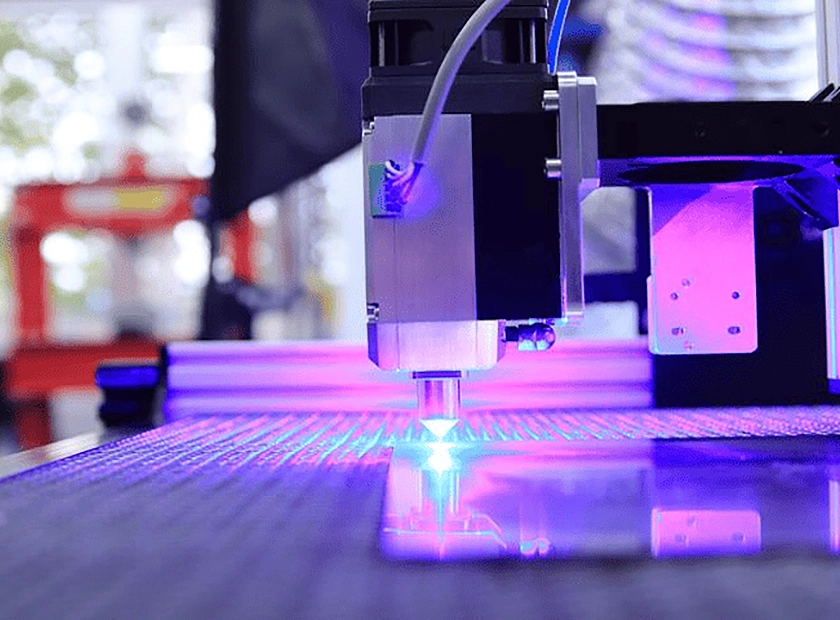

So, what's the magic behind it? At its core, laser cutting employs a high-powered, focused beam of light to slice through various materials – and acrylic is a prime candidate alongside wood, metal, and even fabric. When this intense energy hits acrylic, it precisely melts, vaporizes, or cleanly cuts away the material, leaving behind an impeccably smooth edge. The result? Astonishingly accurate cuts, bringing even the most detailed patterns to life quickly and efficiently.

It's no surprise then, that as the hunger for unique, top-quality acrylic pieces grows, laser cutting is surging in popularity. From solo artists and boutique designers to large-scale manufacturers, everyone is tapping into the power of laser cutting to elevate their acrylic designs and products.

Acrylic art design

Behind the Beam: Understanding the Acrylic Cutting Journey

Getting that perfect laser-cut acrylic piece isn't just a point-and-shoot affair. It's a meticulous process designed for pinpoint accuracy, all while keeping material waste and potential damage to a minimum. Here’s a peek at how it unfolds:

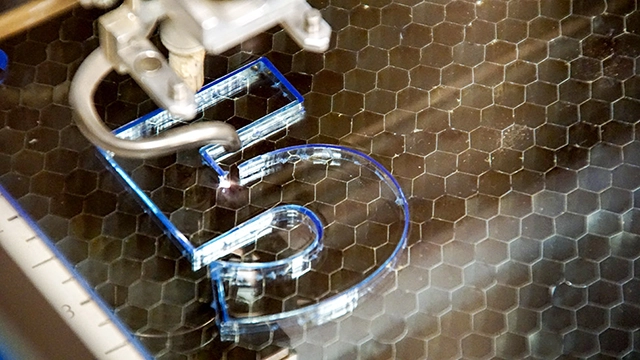

- Digital Blueprint: It all starts with a digital design, crafted using specialized software. This is where intricate patterns, custom shapes, and crisp text take form.

- From Screen to Machine: This digital file is then zapped over to the laser cutting machine. The machine cleverly translates this digital info into precise coordinates, telling the laser exactly where to go.

- The Cut Itself: Now for the action! The laser beam dances across the acrylic surface, concentrating its energy to make those clean, sharp incisions. The heat from the beam melts and vaporizes the acrylic, leaving that signature smooth edge. This can be done over and over to build up complex designs, all while being surprisingly efficient with material.

- The Grand Reveal: Once the cutting symphony is complete, the finished pieces are carefully removed. Any protective film or stray bits are cleared away, unveiling a beautifully crafted acrylic item with those pristine, smooth edges – ready for its starring role in an assembly or display.

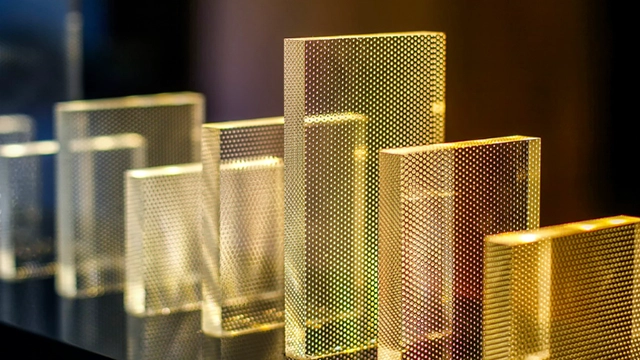

Glossy acrylic edge laser

Laser vs. Old School: A Cut Above the Rest

For ages, methods like sawing or milling were the standard for shaping acrylic. But let's be honest, these older techniques have their downsides, especially when you compare them to the finesse of laser cutting. Here’s where laser cutting truly shines:

- Precision Perfected: Old-school methods often rely on manual work, which can lead to little oopsies and inconsistencies. Laser cutting? It delivers a level of precision and accuracy that’s simply in another league.

- Edge Envy: Laser cutting gifts you with clean, almost polished edges. Traditional methods? They often leave rough or uneven edges that need extra cleanup (sanding or polishing, anyone?).

- Design Freedom Unleashed: Ever tried to create a super-intricate pattern with a saw? It’s a challenge! Laser cutting, however, handles complex designs with grace and ease.

- Less Waste, More Wow: Traditional cutting can be a bit wasteful, with offcuts and corrections adding up. Laser cutting is far more material-savvy, which is better for your budget and the planet.

- Speed Demon: Need a bunch of acrylic parts, like, yesterday? Laser cutting is significantly faster than traditional methods, slashing lead times and often, costs. It’s a win-win.

Smooth edge laser cut acrylic

Why Designers Love Laser-Cut Acrylic?

When it comes to design projects, laser-cut acrylic (you might know it as plexiglass) isn't just another pretty face; it brings some serious muscle to the table:

- Built to Last: This stuff is tough! Acrylic is highly resistant to cracking, chipping, and scratching. That means your creations will look great for a long, long time.

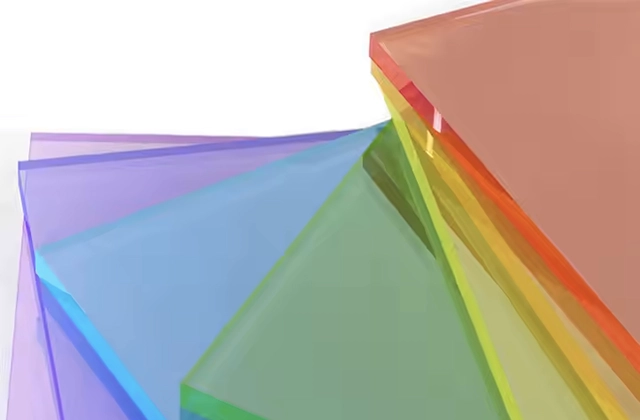

- Seriously Good Looking: Acrylic has a sleek, modern vibe that instantly elevates any design. Plus, laser-cut plexiglass can be made in a dazzling array of colors and finishes. Talk about personalization!

- Light as a Feather (Almost!): Compared to heavyweights like glass or metal, acrylic is refreshingly lightweight. This makes it a breeze to transport and install, especially for bigger projects.

- Designers’ Dream Material: Thanks to laser cutting, bringing complex and delicate designs to life in acrylic is easier than ever. This opens up so many doors for creativity and custom touches.

- Kind to Your Wallet: Often, acrylic is more budget-friendly than materials like glass or metal. That’s great news for designers and clients keeping an eye on the bottom line.

Colored laser cut acrylic

The Future is Bright

There's no doubt about it: laser cutting technology has truly transformed how we think about and work with acrylic. By tapping into its incredible precision, flexibility, and speed, designers and manufacturers are unlocking a whole new realm of creative potential.

Whether it's crafting delicate art pieces, producing sharp-looking signage, or engineering unique architectural elements, laser-cut acrylic simply offers more. If you're aiming for high-quality, custom acrylic work that hits the mark every time, embracing this technology and finding a skilled service provider is key.

And the exciting part? As technology keeps evolving, the horizons for laser-cut acrylic design are only going to get wider. By stepping into the future of acrylic design with laser cutting, you’re not just keeping up – you’re setting the pace, ready to bring even the most ambitious visions to life with stunning accuracy.