A Guide to Quick-Turn & Low-Cost PCB Assembly

Have you finalized your circuit design, only to face the critical question: how do you get it manufactured quickly, reliably, and within budget as a functional PCBA circuit board?

This is more than just finding a supplier.

Choosing the right PCB Assembly partner and strategy will directly impact your product's time-to-market and final cost. This guide draws from our experience as a trusted manufacturer to give you specific, actionable advice.

First, The Critical Distinction: PCB vs. PCBA

In our industry, precise language is the foundation of professionalism.

- PCB (Printed Circuit Board): This is the bare, green (or other color) board containing only the copper traces and conductive pathways. It is the substrate or carrier.

- PCBA (PCB Assembly): This is the process and the final product of mounting and soldering electronic components onto a bare PCB.

In short, a PCB is the skeleton; a PCBA is the fully functional body. Our core service is to provide high-quality PCBA.

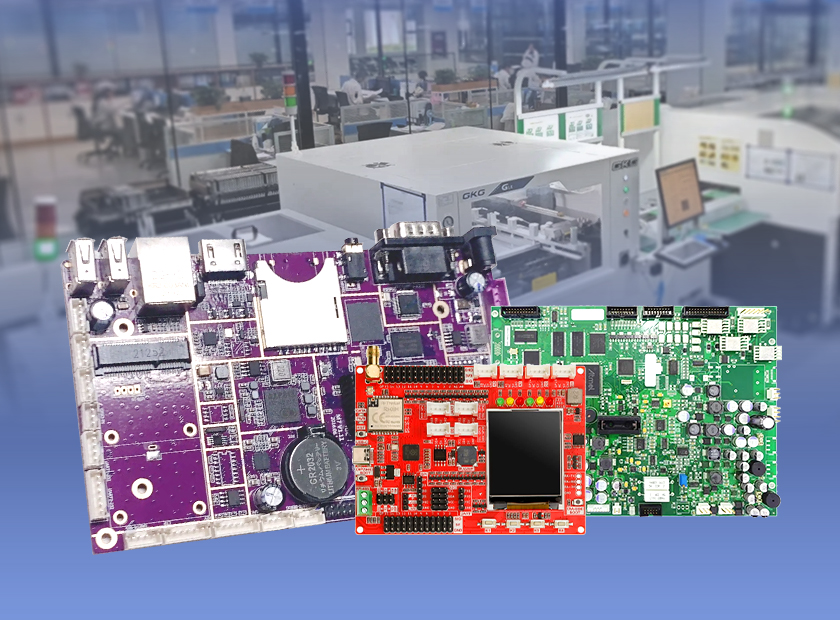

Choosing the Right PCBA Service: Our Offerings

We offer flexible services to match your project's specific needs.

| Service Model | How It Works | Best For |

|---|---|---|

| ✅ Full Turnkey Service | You provide Gerber & BOM files. We handle everything: PCB fabrication, component sourcing, assembly, and testing. | Customers who want a one-stop, hassle-free solution to save time and focus on design. |

| ✅ Partial Turnkey (Kitted) | You provide the Gerber files, BOM, and some or all of the components. We handle the assembly. | Customers who have specific components on hand or prefer to source certain critical parts themselves. |

Our Full Turnkey service is the most popular choice, streamlining your supply chain and ensuring a smooth process from start to finish.

A Deep Dive: The 5 Major Factors Influencing PCBA Cost

"How much does it cost to assemble a PCB?" To help you manage your budget, here are the core factors that drive PCBA pricing.

- The PCB Itself: Size, layer count, material (FR-4, etc.), and special processes like blind/buried vias.

- Components (BOM): The quantity, package types (BGA, QFN), and sourcing difficulty of the components.

- Order Quantity: From our minimum of 5 pieces to 10,000+. Higher volumes lead to a lower cost per unit.

- Assembly Complexity: Component density and the mix of SMT and THT technologies.

- Turnaround Time: We offer quick turn pcb assembly in as fast as 2-3 business days. Standard lead times are more cost-effective for non-urgent projects.

PCB Assembly together

Expert Advice: How to Reduce Your PCBA Costs with Us

Our goal is to be your partner, not just a supplier. Here are actionable tips to lower your costs when working with Elecrow.

- Take Advantage of Our Free DFM Check

Before production, we provide a Free Design for Manufacturability (DFM) Check. Our engineers review your files to identify potential issues that could increase costs or cause delays. This complimentary service is key to optimizing your design from the start. - Optimize Your BOM for Sourcing

We source 100% original components from trusted distributors like Digi-Key, Mouser, Arrow, and Avnet. To reduce costs, try to select commonly available parts in your BOM, as this speeds up sourcing and lowers prices. - Panelize Your Boards

If your PCB is small, providing a panelized design significantly improves our manufacturing efficiency and directly reduces your cost per board. - Provide a Complete Centroid File

A clean and accurate Pick-and-Place (Centroid) file ensures our automated machines can place components perfectly, avoiding costly manual adjustments. - Specify the Correct Quality Standard

All our assembly work complies with the IPC-A-610E Class 2 standard, which is the benchmark for most commercial and industrial electronics. Clearly defining this avoids over-engineering and unnecessary costs associated with higher classes.

PCB Manufacturing with Order

Our Commitment to Quality and Trust

How do we ensure every circuit board we deliver is flawless? It comes down to our certified processes and transparent quality control.

- Authoritative Certifications: Our facilities are ISO 9001:2015 and UL certified, demonstrating our commitment to international quality and safety standards.

- Strict Standards: We strictly adhere to the IPC-A-610E Class 2 industry standard for all assembly workmanship.

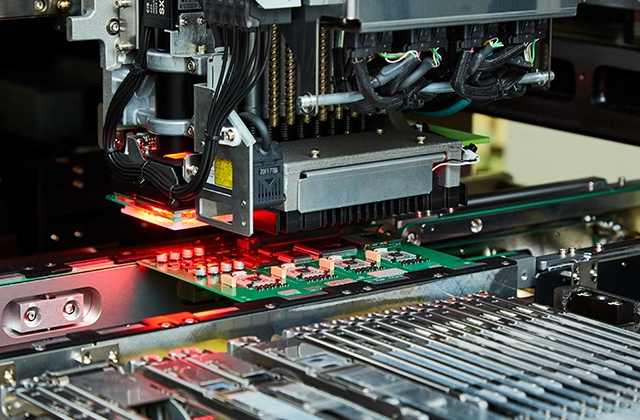

- Advanced Equipment: We utilize leading PCB assembly equipment for high-precision SMT and THT assembly.

- Transparent Inspection: We guarantee quality through a multi-stage inspection process, including Automated Optical Inspection (AOI), X-Ray Inspection for complex packages like BGAs, and final Functional Testing based on your requirements.

Ready to Bring Your Design to Life?

From a single circuit board prototype to high-volume production, we have the capabilities to meet your needs.

Upload your Gerber and BOM files now to receive a free, instant, and transparent quote.