How Electronic PCB Assembly work for Automotive and IoT

PCB Assembly became the Core Engine Automotive and IoT

In today's highly interconnected technological ecosystem, Electronic PCB Assembly (PCBA) is far more than a simple process of soldering components. It is a highly complex engineering discipline that integrates materials science, automation engineering, supply chain management, and rigorous quality control. From conceptual design to the realization of a functional product, PCBA serves as the indispensable link for physical transformation. Whether defining the future of mobility with automotive embedded systems or constructing the vast network of IoT and smart manufacturing, the performance, reliability, and commercial viability of these technologies depend directly on the quality of their underlying PCBA. To truly understand its core value, one must delve into the full-chain technical details—from bare board fabrication to final product testing—and explore how it meets the unique challenges of different cutting-edge sectors.

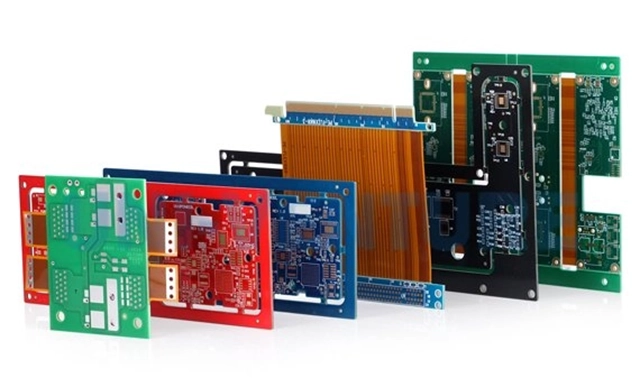

Every exceptional PCBA begins with a high-precision bare board. Printed circuit board manufacturing itself is a complex, multi-step process that defines the upper limit of quality for the subsequent assembly. The choice of substrate material, copper weight, layer stack-up, and surface finish must be meticulously specified based on the electrical performance, thermal management needs, and environmental conditions of the final application. Particularly in the prototyping and small-batch production phases, CNC PCB making technology plays a vital role. At this critical stage, the precision manufacturing services offered by experienced providers like Elecrow become invaluable, as they ensure micron-level accuracy in circuit traces, hole positions, and board outlines, providing an essential physical foundation for high-speed, precise automated placement equipment.

Automotive PCB Prototyping

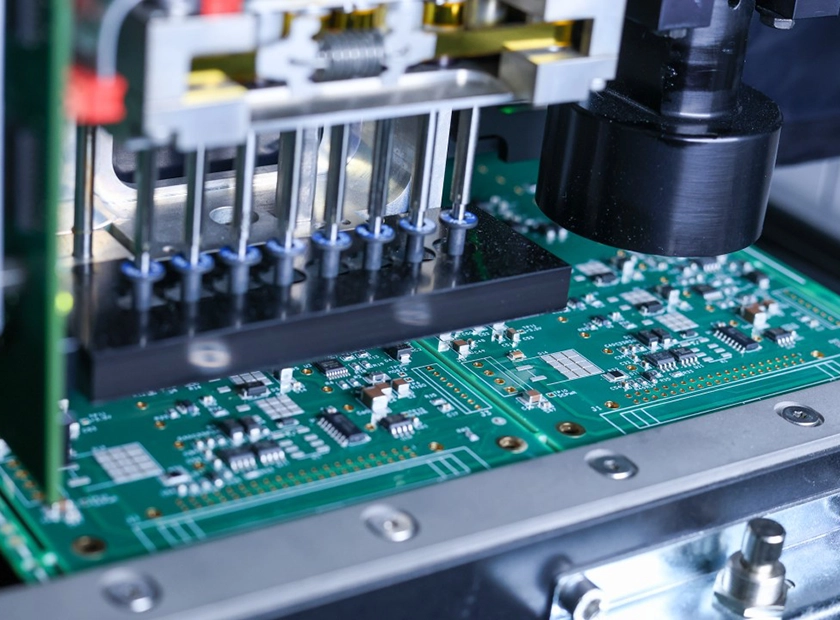

Once a qualified PCB enters the assembly stage, a professional electronic production company initiates a highly automated process dominated by Surface Mount Technology (SMT). The core of this process lies in the meticulous control over details. First, a solder paste printer applies a precise volume of solder paste onto the PCB's pads through a custom stencil; its thickness, shape, and uniformity directly determine the quality of the final solder joints. Next, high-speed pick-and-place machines use vision systems to place components with incredible speed and precision onto their designated coordinates. Subsequently, the board is conveyed through a multi-zone reflow oven, where a precisely controlled thermal profile—one of the most technically demanding aspects of the entire Electronic PCB Assembly process—is applied. Finally, the process concludes with stringent quality inspections, including Automated Optical Inspection (AOI) and X-ray Inspection (AXI), to ensure every PCBA meets its design specifications.

The automotive industry, with its century-long history, has seen every technological leap profoundly marked by advancements in electronics. From the engine control units (ECUs) and car radios of the internal combustion era to today's ubiquitous sensor networks and complex infotainment systems, PCBA has always been the core enabler. As the industry pivots towards electrification and intelligence, this dependency has reached an unprecedented level. Core components like Battery Management Systems (BMS), motor controllers, and autonomous driving domain controllers place demands on PCBA performance and reliability that far exceed those of any previous era.

IOT PCBA

For this reason, the automotive sector has become the ultimate proving ground for PCBA technology. New trends and developments in automotive system engineering, such as autonomous driving platforms and smart cockpits, impose multi-dimensional and unprecedentedly strict requirements on PCBA. These automotive embedded systems must guarantee absolute reliability, with specific challenges manifested in several key areas:

- Tolerance for Extreme Operating Environments: Automotive electronics must function flawlessly across a wide temperature range of -40°C to 125°C while withstanding constant mechanical vibration, shock, and complex electromagnetic interference (EMI). This poses a significant challenge for PCBA material selection, solder joint strength, and circuit protection design.

- Ultra-High Reliability and Long Lifecycles: Unlike consumer electronics, vehicles are designed for lifespans exceeding 15 years or 200,000 kilometers. This means the PCBA and every component on it must have an extremely low failure rate (often measured in PPM, or parts per million) to ensure zero unexpected failures throughout its lifecycle.

- Strict Component-Level Standards: All components used in automotive PCBAs, from microchips to basic resistors and capacitors, must be certified to automotive-grade standards like AEC-Q100 (for integrated circuits) or AEC-Q200 (for passive components).

- Comprehensive Quality Management and Traceability: The production process must strictly adhere to the IATF 16949 quality management system for the automotive industry. Every step, from material receiving to production parameters and final testing, must be meticulously documented and traceable.

- Mandatory Functional Safety (FuSa) Requirements: For safety-critical systems (e.g., braking, steering, autonomous driving), the PCBA design and manufacturing must comply with the ISO 26262 standard. This ensures that even in the event of an electronic failure, the system can enter a predefined safe state to protect occupants.

Meeting all these conditions is the ultimate test of an electronic production company's comprehensive capabilities and represents an extremely high technical and managerial barrier to entry.

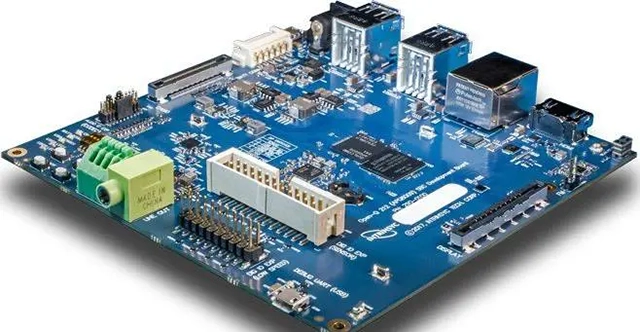

In contrast to the extreme reliability demanded by the automotive sector, IoT and smart manufacturing presents a different set of multifaceted challenges concerning cost, power consumption, form factor, and connectivity. IoT devices often require minimal standby power to extend battery life while integrating complex circuitry—including processors, sensors, and wireless modules—into extremely limited physical spaces. This has driven PCBA towards higher densities, smaller component sizes (like the adoption of 01005 packages), and more complex RF circuit layouts. The sheer market volume in this sector requires PCBA suppliers to possess robust supply chain integration capabilities and highly efficient, high-yield mass production capacity.

In the global electronics supply chain, PCBA in China has become a strategic choice for countless technology companies worldwide, thanks to its mature ecosystem and deep engineering expertise. When selecting a partner, however, the evaluation must go far beyond price comparison. The true value of partners like Elecrow lies in the depth and breadth of their engineering services, setting the standard for what a trustworthy electronic production company should offer. When assessing potential suppliers, key areas to scrutinize include:

- Engineering and Technical Capability: Can they engage early in the project to provide Design for Manufacturability (DFM) and Design for Testability (DFT) analysis, helping to optimize the design and mitigate production risks from the outset?

- Quality Management System: Do they have a robust quality control process, advanced inspection equipment like SPC, AOI, and AXI, and the necessary industry-specific certifications?

- Supply Chain Management: Do they maintain stable and reliable component sourcing channels with full traceability, and can they effectively manage the risks of component shortages and price volatility?

- Project Management and Communication: Is there a clear, transparent project management process and a professional communication channel to ensure timely responses and effective problem-solving?

An outstanding partner can transform a client's design concept into a competitive market-ready product through a rigorous, reliable, and efficient Electronic PCB Assembly process. In conclusion, PCBA is the critical bridge connecting modern technological innovation with market reality. A deep understanding of its technical core and industry applications will empower businesses to make smarter decisions in product development, securing a decisive advantage in a fiercely competitive market.