From Design to Production: 13 Core Principles for PCB Assembly

In the journey of an electronic product from concept to market, PCB design is a critical milestone. However, a design that is perfect only in software may become a bottleneck during mass production if manufacturing considerations are ignored. Design for Assembly (DFA) is the essential bridge connecting design with manufacturing. It is a systematic methodology aimed at simplifying the assembly process, increasing production efficiency, lowering costs, and enhancing product reliability through design optimization.

This article provides a comprehensive PCB Design for Assembly guide, delving into 13 core DFA principles to help your project transition smoothly from blueprint to full-scale production.

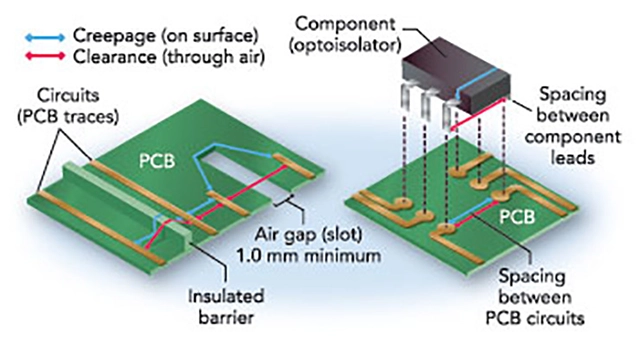

1. Optimize Component Spacing: Reserving Space for Efficient Assembly

Inadequate component spacing is the most fundamental and critical hurdle in assembly. Overly dense layouts can directly lead to production issues such as solder bridging between adjacent pads or preventing the pick-and-place machine's nozzle from accurately placing components. Furthermore, sufficient clearance is vital for Automated Optical Inspection (AOI) and for any subsequent manual debugging or repairs. A common oversight is considering only the XY plane clearance while neglecting Z-axis (height) interference. A tall electrolytic capacitor could obstruct the view of a shorter IC next to it, creating a blind spot for AOI and preventing a thorough inspection of the IC's solder joints.

PCB layout clearance

Best Practice: Even for small components like 0402 resistors and capacitors, maintaining a minimum safe clearance of 10-30 mils is highly recommended. In your EDA tool, create and enable a "placement courtyard" or "place boundary" for each component footprint. This virtual area, slightly larger than the component's physical body, effectively prevents interference during layout. When placing components, also be mindful of separating tall components from shorter ones that require critical inspection or future access, thereby planning ahead for both production and maintenance ease.

2. Strategic Component Selection: Mitigating Risks from the Start

Your component selection strategy should begin during the schematic design phase. Waiting until the design is complete to source parts is a major project management pitfall. Imagine your design relies on a specific microcontroller, only to discover before production that it's globally out of stock with a 52-week lead time. This forces a search for an alternative, which may have a completely different pinout and footprint, necessitating a complete redesign of the core PCB layout. This reactive situation not only consumes valuable time but can also cause you to miss the market window for your product.

Risk Management: Use reliable supplier channels to verify inventory levels, lead times, and the lifecycle status of critical components (e.g., avoid parts marked "NRND - Not Recommended for New Designs"). Creating an Alternate Vendor List (AVL) with at least one pin-compatible replacement for core chips significantly enhances design resilience. Proactively communicating with your PCBA provider, like PCBWay, during the design phase to leverage their supply chain data is an exceptionally wise strategy.

3. Wise Footprint Size Selection: Balancing Density and Manufacturability

The choice of component footprint size directly impacts the manufacturing cost and yield of your PCB. While smaller footprints like 0201 allow for higher integration density, they also impose stricter requirements on placement equipment and process control. Without sacrificing critical performance (such as high-speed signal integrity), opting for slightly larger footprints is often the more prudent choice. This is not just because larger components are easier for pick-and-place machines to handle, but also because their larger pad areas are more tolerant of minor solder paste printing deviations, leading to a higher first-pass yield overall.

Practical Consideration: For standard digital circuits, using a 0402 footprint typically results in higher placement yields and better soldering reliability compared to 0201. Conversely, if an 0805 package already meets all power requirements, there is no need to use a 1206. This helps control the PCB size and, consequently, the raw board cost. The best decision is to choose mainstream, mature footprint technologies that meet design needs, rather than blindly pursuing extreme miniaturization.

4. Balanced Layout: Achieving Uniform Thermal Distribution

Reflow soldering uses high temperatures to melt solder paste and fix components in place. If the thermal mass on the PCB is unevenly distributed—for instance, clustering all large BGAs, power inductors, and connectors together—that area becomes a massive "heat sink." This causes it to heat up much slower during the reflow process. As a result, when smaller components in other areas have perfectly soldered, the solder paste in this "cold zone" may not have fully reached its liquidus temperature, leading to numerous cold solder joints or poor wetting. This thermal imbalance not only affects the initial soldering but also complicates rework; heating a BGA might inadvertently damage a nearby plastic connector due to excessive local temperature.

Thermal Management Strategy: During the layout phase, consciously distribute these high thermal mass components evenly across the board's surface. This promotes more uniform heating as the board passes through the reflow oven, ensuring all solder joints, regardless of size, complete the soldering process within the optimal time window. This is a critical step for improving soldering quality. Think of your PCB as a cookie you're baking; you need to spread the chocolate chips evenly to ensure every bite is delicious.

5. Maintain a Dynamic BOM: Ensuring Flawless Information Accuracy

The Bill of Materials (BOM) is the single source of truth for production, and its accuracy dictates whether manufacturing can proceed smoothly. An inaccurate BOM, whether due to a wrong part number or a vague description, can lead to the procurement of incorrect components, potentially scrapping an entire batch of products. Therefore, BOM management must be an integral part of the entire design process. Often, a designer might change a resistor value during debugging but forget to update the final BOM. This small oversight can escalate into a catastrophic failure during mass production, causing entire batches of products to fail functional tests.

BOM spreadsheet overview

BOM Specification: A professional BOM must include: reference designators, exact quantity, manufacturer name, complete manufacturer part number, and the footprint name consistent with the PCB library. Any modification to a component during the design process must be immediately synchronized across the BOM, schematic, and PCB files to maintain absolute consistency. Using a version control system like Git to manage your design files and BOM is an excellent habit for ensuring this synchronization.

6. Rigorously Verify Footprints: Eliminating Fatal Errors

An incorrect footprint is one of the most expensive and irreversible errors in PCB design. A 0.1mm deviation in pin pitch or a mirrored pin definition will lead to the entire batch of PCBs being scrapped. Never blindly trust unverified footprint libraries. Especially when using libraries downloaded online, standards can vary wildly between contributors. A seemingly correct footprint might have subtle differences in pad size or solder mask opening, which can cause poor wetting or solder balling issues during assembly.

Verification Process: Before using any footprint, meticulously check it against the component's official datasheet, verifying pad dimensions, pin pitch, and the physical outline. A simple yet highly effective method is to **print the PCB footprint layout at a 1:1 scale** and physically place the actual component on it. This hands-on comparison ensures a perfect match. This quick check, taking only a few minutes, can save you weeks of rework and thousands of dollars in losses.

7. Design Clear Silkscreen: Providing a Production Roadmap

The silkscreen layer is the "map" for assembly and testing engineers. Ambiguous or missing information on the silkscreen can significantly decrease production efficiency and increase the likelihood of errors. All critical information should be displayed clearly and legibly. If an IC's Pin 1 indicator is placed underneath the component, or a diode's cathode mark is interrupted by a via, assembly technicians are left to guess the orientation, leading to a high risk of incorrect placement. If a reference designator like "R101" is obscured by another component, technicians will waste valuable time trying to locate it during debugging or repair.

Silkscreen Design Essentials: Ensure every IC has a clear Pin 1 indicator (like a dot or bevel). Every polarized component, such as a diode or electrolytic capacitor, must have an unambiguous polarity marking. Additionally, reference designators (e.g., R1, C1) should be placed adjacent to their respective components, using a legible font and size, and must not be obstructed by vias, pads, or other components. Before exporting your Gerbers, always preview the silkscreen layer alone to check for completeness and clarity.

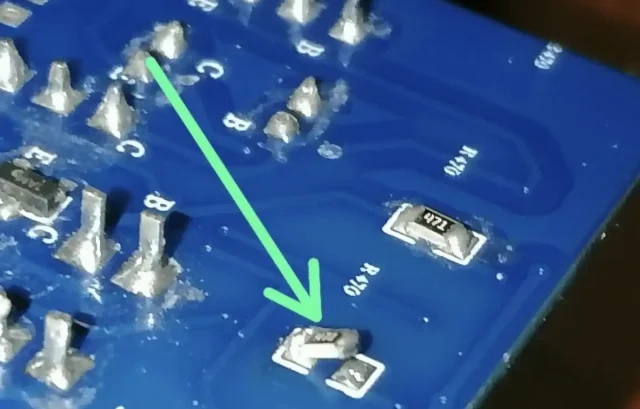

8. Adhere to the Independent Pad Principle: Preventing Tombstoning

In the physics of soldering, each component lead should be connected to its own independent pad. When multiple leads share a single large pad, the surface tension forces of the molten solder become unbalanced. For small two-pin passive components (like chip resistors and capacitors), this causes the pull on one end to be much stronger than the other, lifting that end of the component vertically. This defect, known as "tombstoning," is a major cause of yield loss on automated production lines, especially in high-density designs, and requires costly manual rework.

Typical Tombstone Problem

Design Rule: Even when a large copper area is needed for thermal dissipation or high current, use a thermal relief connection. A thermal relief connects the pad to the copper plane via several thin traces. This maintains the electrical connection while creating a thermal barrier, ensuring the pad heats up at the same rate as the component, thus balancing the soldering forces.

9. Unify Manufacturing Processes: Simplifying for Cost Reduction

Mixing Surface Mount Technology (SMT) and Through-Hole Technology (THT) on the same board significantly increases production complexity and cost. SMT assembly is typically a fully automated reflow soldering process, whereas THT requires an additional wave soldering step or expensive manual soldering. Adding an extra process for just one or two non-essential through-hole components is uneconomical. It not only means two different sets of equipment and line setups but also adds complexity to material flow and WIP (Work-in-Progress) management, with each additional step introducing new potential quality risks.

Process Optimization: During the design phase, actively search for SMT alternatives for your required components. Today, many traditional through-hole components, like connectors and inductors, have SMT equivalents. If a through-hole component is unavoidable, group them all together on one side of the PCB to facilitate a single pass of wave soldering or to streamline manual insertion.

10. Standardize Soldering Profiles: Avoiding Lead/Lead-Free Conflicts

Leaded solder has a much lower melting point (around 183°C) than lead-free solder (around 217-227°C), meaning they require completely different reflow temperature profiles. Mixing components with different soldering standards on one board creates a dilemma for the manufacturer. Using a high-temperature lead-free profile might damage leaded components not rated for that heat. Conversely, using a lower-temperature leaded profile will fail to properly melt the lead-free solder joints, leading to poor reliability and early-life failures.

Regulatory Compliance: Based on the regulations of the product's target market (e.g., the EU's RoHS directive), establish a single soldering standard (leaded or lead-free) for the entire board. Ensure all selected components are compliant with this standard. Clearly specifying the required soldering process in the BOM is the clearest instruction you can give a manufacturer to prevent any confusion.

11. Monitor the Supply Chain: Planning for Long-Term Component Availability

For products intended for long-term production and maintenance, the stability of the component supply chain is paramount. Selecting a chip that is nearing its End-of-Life (EOL) is like planting a time bomb in your product's future. You might be able to source small quantities for prototypes, but by the time you reach mass production, the chip may be completely discontinued. This would force you into a costly and time-consuming redesign process, involving not just hardware changes but potentially also firmware adaptation and product re-certification.

Long-Term Vision: When selecting parts, actively check their lifecycle status. Prioritize components marked as "Active" or "In Production." For the product's core controllers or critical ICs, it's especially important to inquire about the manufacturer's longevity program, which is crucial for products in the medical, industrial, and automotive sectors.

12. Leverage One-Stop Services: Simplifying Complex Material Management

Component sourcing, inspection, and warehousing are specialized and complex supply chain functions. For most design teams, handling these tasks internally is not only time-consuming but also fraught with risks, such as sourcing counterfeit or inconsistent batches of materials. A single bad batch of components can lead to inconsistent product performance, creating a nightmare for customer support. Dealing with multiple vendors, managing different lead times, and coordinating logistics is a significant administrative overhead in itself.

Professional Collaboration: By choosing a vendor like PCBWay that offers one-stop services for PCB manufacturing, component sourcing, and PCBA, you gain access to a professional procurement and supply chain team. They leverage their purchasing scale and stringent supplier vetting processes to ensure component quality and timely delivery, allowing you to focus on your core design work. You submit a complete set of design files and receive fully assembled, functional boards, dramatically accelerating the path from concept to physical product.

13. Perform a DFM Check: The Final Quality "Firewall"

Before sending your final design files (like Gerbers) to the factory, performing a comprehensive Design for Manufacturability (DFM) check is an indispensable step. It's as crucial as code review before a software release. Many seemingly minor design flaws, such as a solder mask sliver that is too narrow and might break off during production, or an isolated copper island (dead copper) that could detach and cause a short, can lead to unexpected quality issues during mass production. These are issues that are difficult to spot with a manual review.

Automated Review: Utilize the free online DFM tools provided by your manufacturer. These tools can automatically flag hundreds of potential issues, such as copper-to-edge clearance, drill hole aspect ratios, and pad-to-pad spacing violations, and provide actionable feedback. This allows you to correct these problems at the design stage—the cheapest point to fix them—and is an essential part of the modern PCB design workflow.

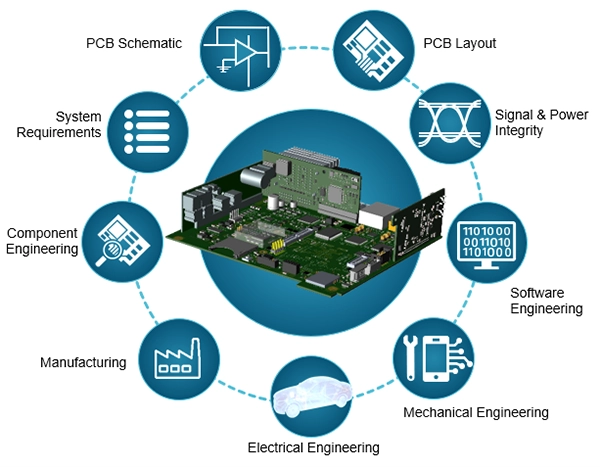

From Designer to Product Engineer

Integrating Design for Assembly (DFA) principles into your daily workflow will not only significantly improve your first-pass prototype success rate but will also fundamentally lower total product costs and shorten time-to-market. It represents a shift in mindset from being just a "designer" to becoming a "product engineer." By considering manufacturability in every detail of your design, you will truly achieve a seamless transition from creative idea to reliable, mass-producible product.