Top 5 Common PCB Soldering Mistakes & How to Identify and Fix Them

Top 5 Common PCB Soldering Mistakes & How to Identify and Fix Them

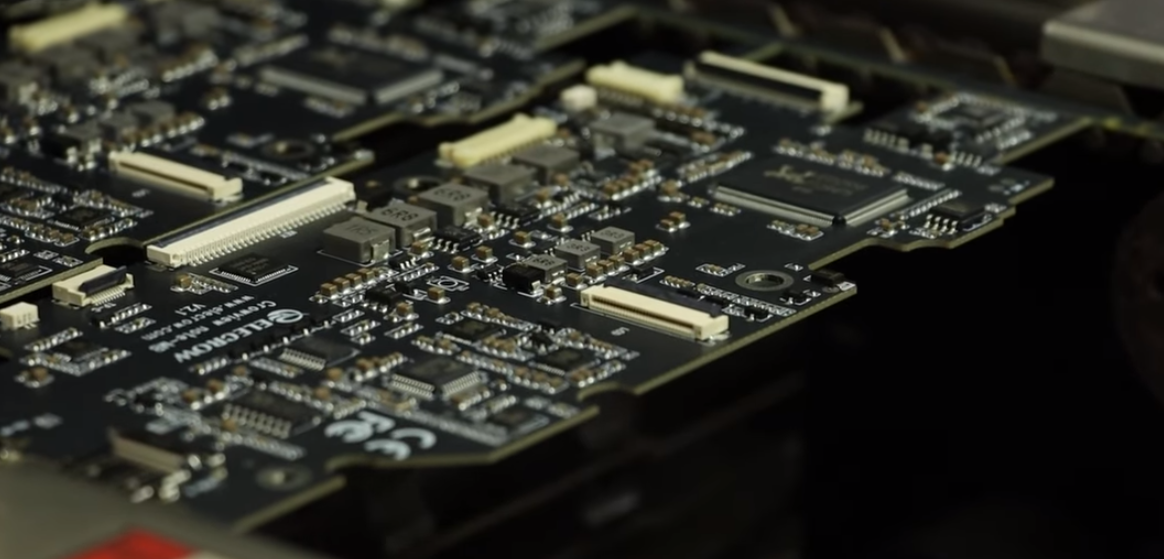

Soldering is often described as the "glue" of the electronics world. When done correctly, it creates a perfect bridge for electricity to flow through your gadgets. But for beginners, a simple DIY project can quickly turn into a nightmare of smoking flux and ruined circuit boards.

If you’ve ever looked at a messy joint and wondered, "Why isn't my circuit working?"—you aren't alone.

In this guide, we’ll break down the most common soldering mistakes that ruin your PCB and, more importantly, how to fix them like a pro.

❤ What Does a Perfect Solder Joint Look Like?

First, let's understand what a perfect solder joint looks like. The appearance of a perfect joint depends on whether you are using traditional leaded solder or modern lead-free solder, as well as the type of component (through-hole vs. surface mount).

1. General Visual Characteristics

Regardless of the type of solder, all high-quality joints share these features:

● The "Concave" Fillet: A good joint should look like a small ramp or a "mountain" with sloping sides (a concave shape). It should smoothly transition from the component lead to the circuit board pad.

● Proper Wetting: The solder should look like it has "melted into" the metal surfaces, rather than just sitting on top of them. This is called wetting. The edges where the solder meets the pad should be thin and feather out smoothly.

● Complete Coverage: The solder must cover the entire pad. If you can see the copper of the pad underneath the solder at the edges, the joint is "starved."

● No Defects: There should be no visible cracks, pinholes (tiny air bubbles), or "bridges" (solder touching an adjacent pin).

2. Leaded vs. Lead-Free Appearance

● Leaded Solder (60/40 or 63/37): A perfect joint is mirror-shiny and smooth. A dull or grainy leaded joint usually indicates a "cold joint" (not enough heat) or that the joint was moved while cooling.

● Lead-Free Solder (SAC305, etc.): A perfect joint is typically matte or dull grey. It may even look slightly grainy. This is normal and does not mean the joint is weak.

3. Through-Hole vs. Surface Mount (SMT)

● Through-Hole (THT): Often called the "Hershey’s Kiss" or "Chocolate Kiss" shape. The solder should flow through the hole to the other side (barrel fill), ideally filling 75% to 100% of the hole. On the solder side, it should form a neat, sloping cone around the lead.

● Surface Mount (SMT): Because SMT pads are flat, the "fillet" (the ramp of solder) is crucial. It should climb up the side of the component's metal end-cap (the "toe") and spread across the width of the pad.

❤ The Top Soldering Mistakes (And Their Fixes)

Mistake #1: The Cold Solder Joint

● The Problem: A cold solder joint happens when the solder doesn't melt completely or the joint wasn't heated enough before the solder was applied. The iron wasn't hot enough, or the joint was moved before it cooled.

● How to spot it: The joint looks dull, grainy, or lumpy instead of shiny and smooth. It often resembles a ball sitting on top of the pad rather than a cone.

● How to Fix It:

Apply Flux: Add a small amount of fresh flux to the joint.

Reheat: Touch your soldering iron tip to the joint until the solder reflows into a liquid state.

Add Fresh Solder: Feed a tiny bit of new solder into the joint to help the heat transfer.

Keep it Still: Hold the component perfectly steady for 3–5 seconds until the solder hardens.

Mistake #2: Solder Bridging

● The Problem: A "bridge" of solder connecting two adjacent pins or pads that should be separate. This could be due to using too much solder or an oversized soldering iron tip. This causes a short circuit, which can permanently fry your components the moment you turn the power on.

● How to spot it: You’ll see a literal "bridge" of silver connecting two separate connections.

● How to Fix It:

Don’t try to "wipe" it away with your iron—that usually makes it worse. Instead, use a solder sucker (desoldering pump) or solder wick (braided copper) to soak up the excess. (Place a piece of copper desoldering wick over the bridge and press your iron onto it. The wick will "soak up" the excess solder like a sponge.)

Mistake #3: Overheating and Lifted Pads

● The Problem: If you hold your soldering iron on the board for too long (usually more than 3–5 seconds), you risk lifting the pad. This could be because the soldering iron stayed on the pad for too long, or the temperature was set too high. Once a pad is lifted, the connection to the internal circuit trace is broken.

● How to spot it: The copper pad actually peels away from the green PCB substrate.

● How to fix it:

If the pad is completely gone, you’ll need to perform a "trace repair." This involves using a tiny jumper wire to bypass the broken pad and connect directly to the next point in the circuit. Prevention is key here: keep your iron between 330°C and 370°C (625°F - 700°F)

Mistake #4: Insufficient Wetting (The "Ball" Effect)

● The Problem: The solder forms a round ball on the component lead but refuses to "stick" to the PCB pad. This usually happens because the pad is dirty or oxidized. Solder needs a clean, hot surface to "wet" (bond) properly.

● How to spot it: The solder forms a bead or ball on the lead but refuses to spread onto the PCB pad.

● How to fix it:

Clean the area with isopropyl alcohol (99%) and a cotton swab. Apply flux to the area and try again. (Flux removes oxidation and helps the solder "wet" the surface)

Mistake #5: Solder Starved / Excessive Solder

● The Problem: Finding the "Goldilocks" amount of solder is a common beginner struggle. If the Solder is Starved, it’s mechanically weak and prone to cracking. If there is excessive solder, you can't tell if the connection underneath is actually good.

● How to spot it: Solder Starved: Not enough solder was used. The joint looks "thin," and you can see the hole in the PCB; Excessive Solder: You’ve used so much that the joint looks like a giant bulbous grape.

● How to fix it:

For starved joints, simply add a tiny bit more solder, For excessive joints, use a solder sucker or wick to remove the excess until you see a nice, concave "volcano" shape.

❤ Some Tips for Soldering Success

1. Use Flux: Flux is your best friend. It cleans the metal and helps the solder flow exactly where it’s supposed to go.

2. Clean Your Tip: A dirty, oxidized iron tip won't transfer heat. Wipe your tip on a brass sponge or wet sponge frequently.

3. Tin the tip: Always keep a tiny bit of fresh solder on the tip to prevent oxidation.

4. Heat the joint, not the solder: Touch the iron to both the pad and the lead simultaneously, then "feed" the solder into the heated joint.

❤ Conclusion

Soldering is a "practice makes perfect" skill. Don't be discouraged if your first board looks a bit messy! By recognizing these common mistakes, you can troubleshoot your projects faster and ensure your electronics last for years.

Tips:

While fixing a few bad joints is a great way to learn, manual soldering can be risky for high-stakes projects or complex designs. If you’re looking for a more perfect solder joint and want to avoid the headache of troubleshooting, consider having a professional PCBA manufacturer do it for you. Elecrow has over 10 years of experience in the PCBA field, offering affordable, high-quality assembly for makers and engineers alike.

[Get a Professional PCBA Quote from Elecrow Today]