Currency

Elecrow Blogs

-

January 14, 2019Hey guys,we’ll have a seven-day Chinese Spring Festival holiday from 4th Feb. 2019 to 11th Feb. 2019. In the meantime, we can not process the orders but you can still place the orders because the perfect arrangements internally so that they can be processed efficiently as soon as we get back on 11th Feb. This is a chart for checking our schedule easily.

![X}MB{_L$CS]IMYQ8N_5_J0M](https://www.elecrow.com/media/magefan_blog/2019/01/XMB_LCSIMYQ8N_5_J0M.png) Here's our explanation of what's on the agenda.

1.For

Here's our explanation of what's on the agenda.

1.For

-

January 11, 2019Considering the wide use of micro:bit and electromagnetic lock, we made a video that combines the two to apply in life. What electromagnetic lock is? Electromagnetic lock is a locking device that consists of an electromagnet and an armature plate. There are two main types of electric locking devices. Locking devices can be either "fail safe" or "fail secure". Electromagnetic locks are fail-safe by design. (Fail-safe means that if the power goes off the door will be unlocked).

-

December 24, 2018As Christmas is coming, we at Elecrow cannot forget even for a moment our hard effort during the year on working on our CrowPi, from sketching an idea to a reality of successful Kick-starter campaign! We decided to celebrate this Christmas with a special xmas special project using the CrowPi! We all know that during Christmas there is nothing better than sitting under the tree with the entire family and singing Christmas songs, why sing alone when you can have a melody singing for you? Our special project will allow your CrowPi to “sing” some Christmas songs for you using the on-board buzzer. We’ve already created an example that

-

December 14, 2018Last week, my niece came over and picked up the phone to show me the flappy bird game she played. But a few minutes later, her mother took the phone away, then she was a heartbreaking cry and rolled on the ground. When I looked at her watery eyes, as her uncle, I thought of a plan - use Python to program the "Flappy bird" game on CrowPi to save my niece. Her mother won't let her play the phone because she thinks that the phone will only affect her learning and let her indulge in the virtual world of the Internet. Therefor , CrowPi must be a wonderful choice. CrowPi is based on learning and entertainment. It allows users to learn while playing, in order to stimulate users' interest in learning, so as to maximize

-

December 13, 2018We have been doing with the CrowPi Python Lessons to encourage people to learn electronics, computer science and programming these days.And now they are done so you can do something by yourself with your CrowPi. As we all know, python is an interpreted, high-level, general-purpose programming language, and now is commonly used in artificial intelligence projects and extensively used in the information security industry, including in exploit development.That’s the reason why we worked out this series of videos to teach you how to programming in python with CrowPi . In addition, you can master the basic common knowledge

-

November 30, 2018My neighbor has a little girl with bad arithmetic. This is a headache when her parents direct her arithmetic, so I want to use Crowpi to program a simple calculator to help people who are not good at computing. My idea is to use the 4 independent buttons on Crowpi as +, - , *, /, and then use the 10 buttons on the matrix button to do 0-9 respectively.When I press these buttons, Crowpi Lcd can display the contents of the button I pressed. When I want to get the result, just touch the touch sensor and it will automatically display the result on the LCD. With the basic ideas, let's get started. Of course, the first thing to do is always to import the modules we want to use. import math import time

-

November 15, 2018This is the fourth year Elecrow provide free prototyping for Christmas theme PCB and hold the competition to encourage the makers to create interesting Christmas projects. Free Prototyping, coupon code: ChristmasPCB The coupon worth $4.9, can be used 500 times at most. It will expire on 26th. Dec. and each person can only use the coupon once. The coupon is especially for PCB manufacturing service with Christmas theme design. You can apply the discount code on the checkout page as below. BTW, 10pcs 10cm*10cm max PCB prototyping is $4.9 on the PCB prototyping order page.

-

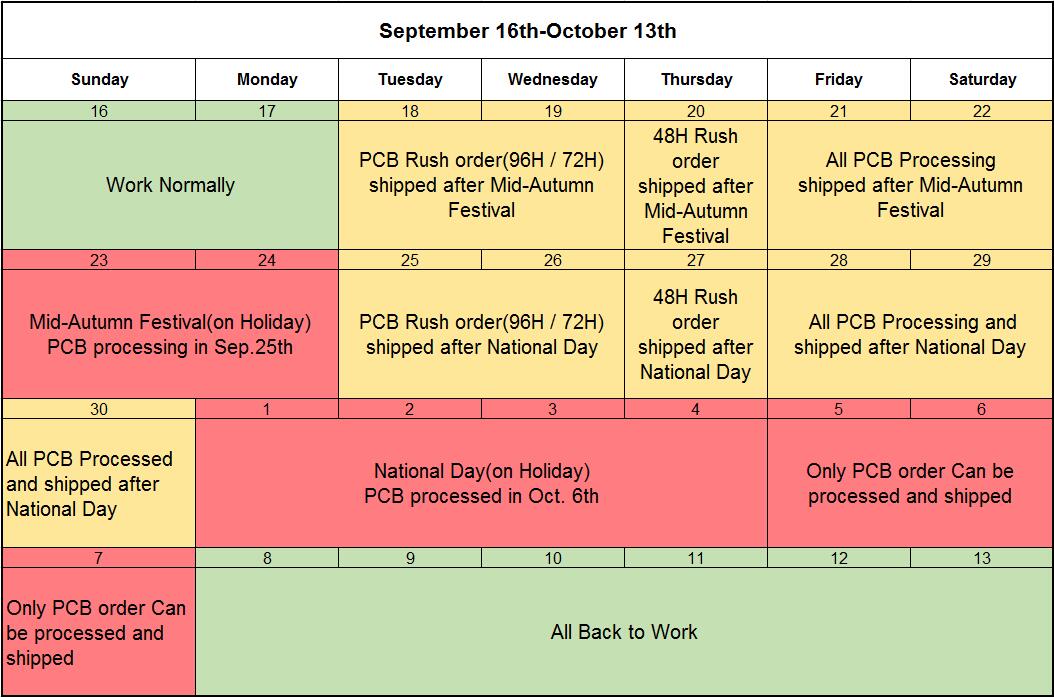

September 18, 2018We will have Mid-autumn festival(22nd- 23rd Sep.) and National Day(1st- 7th, Oct.) Vacation. Please arrange your order in advance.

Green highlights stands for regular working days. All orders can be processed and shipped as normal.

Yellow highlights stands for days which may bring possible shipping delay of your PCB and product orders.

Red highlights stands for the vacation days. Emails can not be replied promptly. In order to decrease the PCB service delay, we will begin to process PCB manufacturing orders on on 5th. Oct.

All orders can be placed during the holiday.

Green highlights stands for regular working days. All orders can be processed and shipped as normal.

Yellow highlights stands for days which may bring possible shipping delay of your PCB and product orders.

Red highlights stands for the vacation days. Emails can not be replied promptly. In order to decrease the PCB service delay, we will begin to process PCB manufacturing orders on on 5th. Oct.

All orders can be placed during the holiday.

-

June 16, 2018

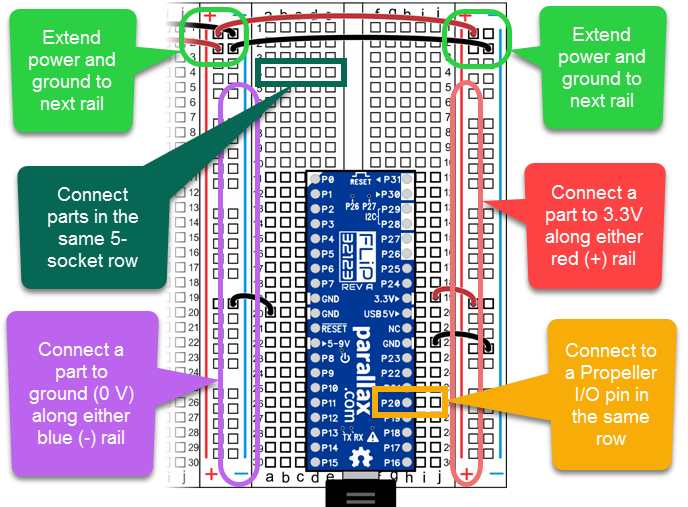

Preview one breadboard usage picture first. And you can learn how the pins connected in one breadboard and how to use it. The following is some basic information about breadboard. What is a breadboard? A breadboard is a rectangular plastic board with a bunch of arrayed tiny holes in it. You can easily insert electronic components into these holes to make up a connective circuit for prototyping or testing. There are different sizes and different colors of breadboards like these. You can visit this page to purchase breadboards in good price.

-

May 10, 2018Living on Kickstarter for a week, CrowPi has reached $27,453 covering 91% of the funding goal, it’s just a short way left to bring it to life. But our expectation is far more than bringing it to the hundreds of backers, we expect CrowPi to lead a crowd of young and potential makers to not only consume technology but also create incredible technology. CrowPi is born with the mission of “lead people go from zero to hero with Raspberry Pi”, more than that, CrowPi is designed to be able to make your making easier, so, let’s see what makes it different - the 10 highlights of CrowPi! CrowPi is Raspberry Pi prototyping board attached to 7inch HD LCD touch display with expansion possibilities to add camera & speakers. What highlights CrowPi?