Story

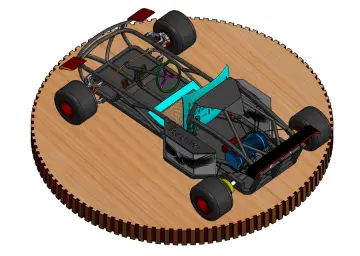

This project presents a detailed 3D model of an Audi A7, created completely from scratch using SolidWorks. The purpose of this model was mainly for fun and personal skill development, rather than as part of an academic or industrial project. It reflects my growing interest in surface modeling and automotive design, showing how complex curves and realistic car shapes can be achieved through careful control of surfaces in SolidWorks.The modeling process began by importing blueprint reference images of the Audi A7 from different views — front, top, side, and rear. These images were aligned within the SolidWorks workspace to provide an accurate foundation for proportions and main body lines. The early stage focused on defining the major surfaces of the hood, roofline, and sides. I mainly used surface tools such as Surface Loft, Boundary Surface, Extruded Surface, and Filled Surface. The goal was to maintain smooth transitions between panels while preserving the aerodynamic and elegant profile characteristic of the Audi A7.I designed roughly half of the car manually using these surface modeling tools. Once I was satisfied with the surface quality and curvature flow on that half, I used the Mirror command to generate the other side of the car. This approach ensured perfect symmetry and reduced the modeling time significantly. After mirroring, I carefully examined the edges to fix any gaps or misalignments and to make the entire body appear seamless and continuous.The entire modeling process took around three days of consistent work. Each day involved refining the shape, adjusting the control curves, and ensuring that the reflections across the body looked natural. The biggest challenge was maintaining curvature continuity (G2 smoothness) across surfaces, especially around complex areas like the headlights, front bumper, and roof intersections. These areas required extra attention to avoid visible surface breaks or shading issues during rendering.Although this project was created purely for fun, it can be easily adapted for 3D printing. By adding wall thickness to the surface model and converting it into a solid body, the design can be exported as an STL file. Once converted, it can be printed using FDM or SLA technology. This would make the model suitable for creating a small-scale prototype, a collectible model car, or even an educational display piece demonstrating automotive design principles.The project demonstrates how SolidWorks can be used effectively for freeform design and not just for mechanical parts. It shows the potential of the software in artistic and industrial design applications, where both creativity and precision are required. Working on this Audi A7 model also helped me improve my ability to visualize 3D surfaces, control geometric curvature, and apply professional modeling workflows typically used in the automotive industry.Overall, this project was a rewarding and enjoyable experience. It helped me better understand how digital design tools can turn creative ideas into tangible 3D objects.Due to the large file size, I was unable to upload the SolidWorks files directly here. If you would like to download the complete project files, please visit the external link provided below.