Story

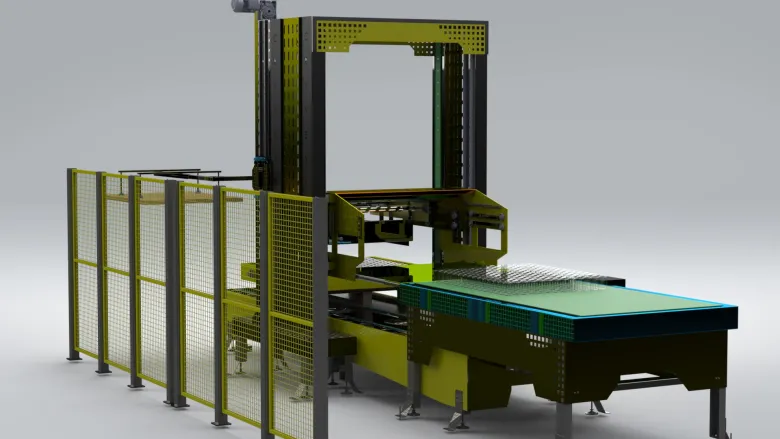

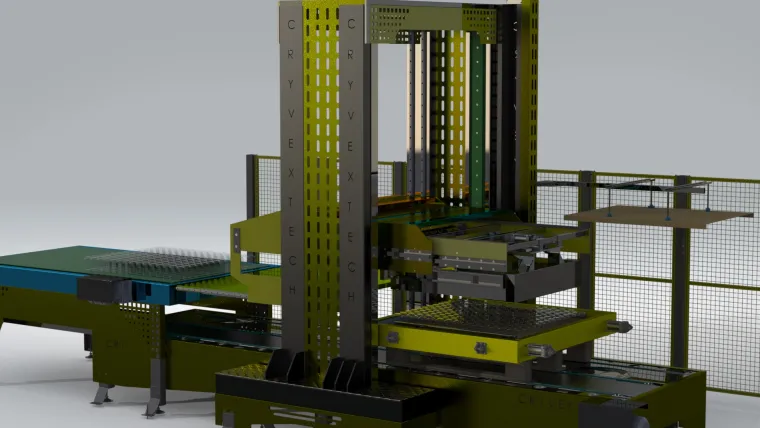

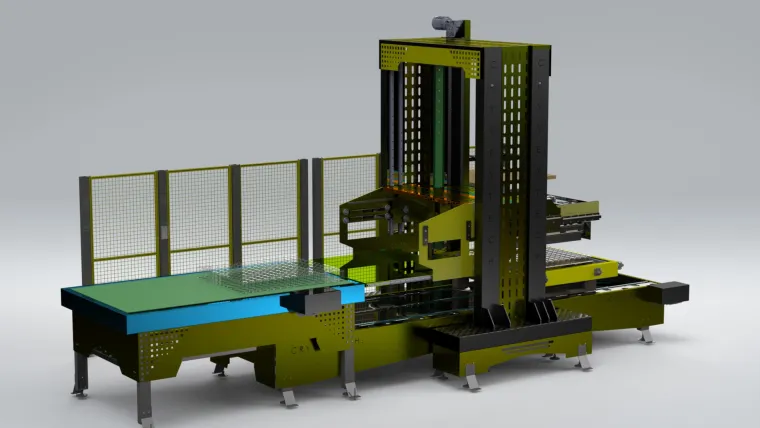

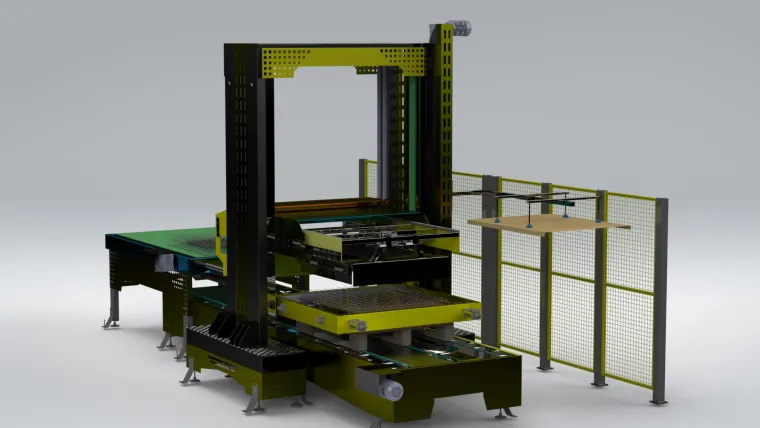

Project Overview — What is this project?

This project is an Automatic, Modular Depalletizer engineered to unload all types of jars and cans (glass, metal, plastic — varying diameters and heights) from industrial pallets. The machine combines a servo-driven gantry, mechanical grippers, an on-demand vacuum separator, and QR-based product recognition to automatically calibrate itself for each pallet type. It is designed for production lines that require fast, safe, low-downtime pallet unloading with easy maintenance and full Industry-4.0 integration.

Key specs (as implemented in this prototype):

-

Overall dimensions: 6500 × 2300 × 3300 mm (L×W×H)

-

Capacity range (by container type & configuration): 8–20 boxes/min

-

Typical pallet load: ~40–120 boxes/pallet (container size dependent)

-

Vacuum separator pump recommendation: 40–80 m³/h (used intermittently only for layer separation)

-

Modular multi-head options: 2–4 heads (quick-change adaptors for different container sizes)

-

Controls: PLC + HMI, Ethernet / OPC-UA connectivity, optional Android monitoring app

How it works — functional flow

-

Pallet arrives on the infeed conveyor and is stopped at the work station.

-

QR reader scans pallet tag → PLC reads product profile (container diameter/height, layer map, handling rules).

-

Height sensors (lidar/ultrasonic/photocell) measure pallet top; PLC computes Z-offset and pick positions.

-

Gantry moves gripper head(s) to target coordinates. Mechanical grippers perform the primary pick; vacuum engages only if a layer needs separation or delicate handling.

-

Picked boxes are placed on buffer conveyors for downstream processes.

-

System logs the operation; optional mobile app shows live status, pallet count, and alerts.

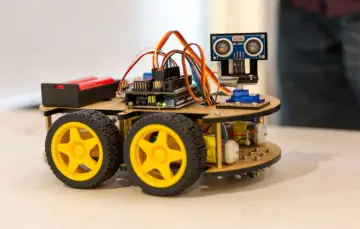

Step-by-step Build & Implementation Tutorial

This is a practical walkthrough — aim to include photos/videos at each major step.

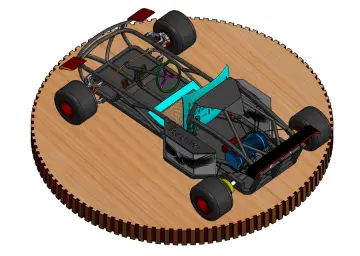

1. Mechanical Design

-

Create frame drawing (steel square tube frame sized to 6500×2300 mm footprint).

-

Design gantry rails and carriage; select hardened linear rails or profile rails for long life.

-

Design modular head plate to accept quick-change adaptors (pin + cam-lock system).

Deliverables: 3D CAD assembly (STEP), exploded parts list, BOM.

2. Gripper & Nozzle System

-

Implement mechanical grippers for general cases (two-jaw soft face).

-

Design silicone vacuum cups and quick-release nozzle adaptors for different diameters.

-

Implement a simple locking latch on each adaptor for tool-free replacement.

Tip: Make adaptors symmetrical and keyed — prevents wrong orientation.

3. Vacuum Separator Module

-

Choose pump 40–80 m³/h with vacuum reservoir and solenoid valves.

-

Integrate a vacuum sensor and a small filter/regulator assembly.

-

Use vacuum only for layer separation; control via PLC IO to minimize wear.

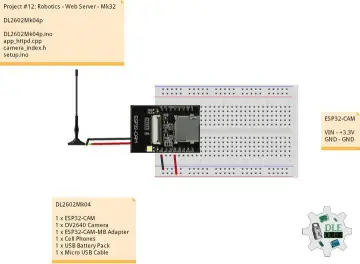

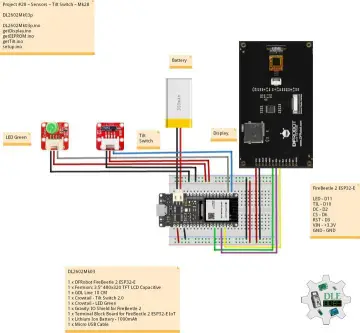

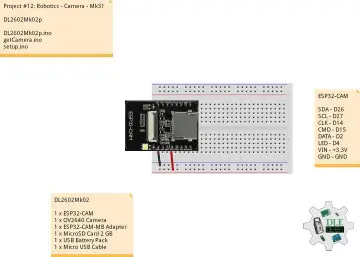

4. Sensors & QR Integration

-

Mount a QR imager at pallet entry. Store a mapping table (QR → product profile) in PLC or a small local DB.

-

Add pallet top sensor (lidar or ultrasonic) and layer presence sensors at gantry positions.

Calibration routine: on first pallet, read QR → measure top height → compute pick Z for each layer → save to session.

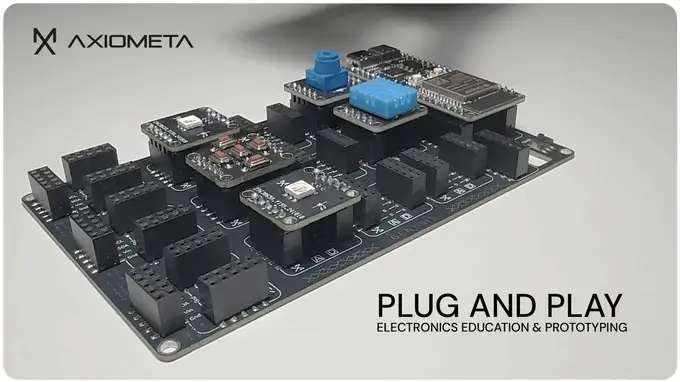

5. Electrical & Control

-

PLC (Siemens / Beckhoff recommended) + servo drives for X/Y/Z axes.

-

HMI screens: Manual/Auto/Service, live diagnostics, calibration wizard.

-

Implement OPC-UA / MQTT for remote telemetry and Android app feed.

6. Software & Logic

-

Create state machine: Idle → Scan → Measure → PickCycle → Place → Log.

-

Implement safety interlocks, light curtain inputs, and E-stop handling.

-

Build calibration routine that blends QR profile with sensor readback for ±2–5 mm accuracy.

7. Commissioning & Testing

-

Dry run with dummies; validate coordinates, gripper force, and vacuum timing.

-

Test across smallest → largest containers; measure cycle time and adjust motion profiles.

-

Run endurance test (8 hours) and log error rates.

Maintenance Plan (short & essential)

-

Daily: Visual check of frame, sensor lenses, conveyor jams; verify HMI alarms are clear.

-

Weekly: Inspect vacuum filters, quick-change adaptor locks, lubrication points on rails.

-

Monthly: Check belt tensions, encoder feedback consistency, safety circuit test.

-

Quarterly: Replace vacuum filter elements, check servo motor couplings, run firmware/PLC backup.

-

Spare parts: Keep extra vacuum cups, nozzle adaptors, a spare QR imager, and critical fuses/drives on hand.

Common Pitfalls & Troubleshooting

-

Poor QR readability: ensure clean labels, consistent placement and proper illumination.

-

Overuse of vacuum: using vacuum for primary pick increases wear; use mechanical grippers as default.

-

Sensor misalignment: causes misplaced picks — design robust mounts and perform daily sensor checks.

-

Too aggressive motion profiles: increase jerk/acceleration gradually to avoid jar breakage.

-

Improper nozzle selection: mismatched cup size causes slippage — use quick change adaptors and a small verification pick.

Community Value — why share this?

This design demonstrates a pragmatic combination of mechanical reliability, sensor-driven calibration, and low-maintenance automation tailored for small to medium-scale production. Sharing CAD, control logic templates, and a maintenance checklist helps other engineers avoid common integration issues and accelerates deployment on diverse product lines.

If you want, I can now:

-

Convert this into a 500+ word submission suitable for Elecrow’s contest,

-

Produce the short 500-character elevator pitch variation, or

-

Generate the file list & captions ready to attach with your GrabCAD upload. Which one do you want next?