Story

Introduction

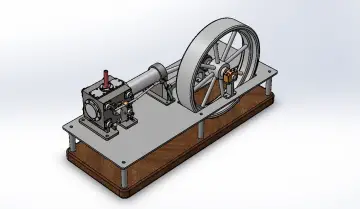

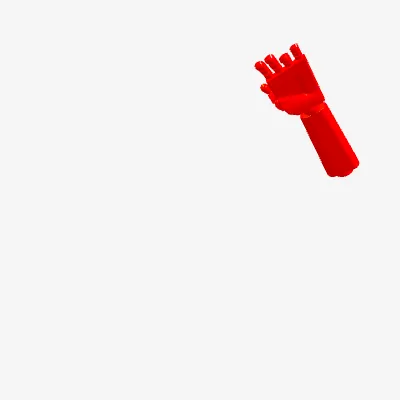

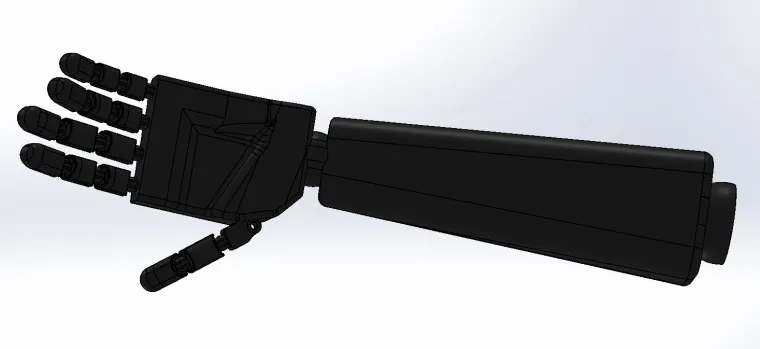

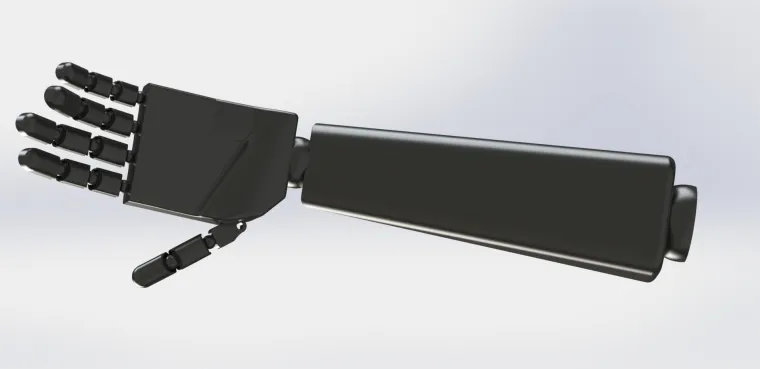

The Bionic Palm and Elbow-till-Hand Assembly is a detailed CAD representation of a next-generation prosthetic limb, designed to replicate natural human arm movement from the elbow to the fingertips. Inspired by modern advancements in robotics and biomechanics, this design focuses on combining functionality, ergonomics, and realistic articulation. The goal of this model is to showcase a mechanical structure that mirrors the dexterity of the human hand and the controlled motion of the elbow, making it suitable for both educational and research purposes in prosthetic design and biomechanical engineering.

Design Overview

This CAD model is structured into two major sections — the elbow joint assembly and the bionic palm mechanism. The elbow segment incorporates a rotational joint capable of simulating flexion and extension similar to the natural arm. It features mechanical linkages and pivot points that ensure smooth and controllable motion. The forearm section is designed with a lightweight framework to provide structural stability while minimizing mass, making it practical for 3D printing and real-world prototyping.

The bionic palm is the centerpiece of this design. It consists of five fingers, each modeled with multiple phalange segments and revolute joints that mimic natural bending and gripping motion. The internal layout accommodates actuators, tendons, or linkage-driven systems depending on the chosen implementation. This modularity allows the model to be adapted for both passive and active control systems — whether controlled via motors, servos, or even myoelectric sensors in future versions.

Features

Anatomical Accuracy: Designed with realistic proportions and motion ranges that align with the geometry of the human arm.

Fully Articulated Fingers: Each finger is independently jointed to replicate natural grasping, holding, and precision gestures.

Modular Joint Design: The elbow and wrist joints are separated for easy assembly, customization, or motor integration.

3D-Printable Ready: The model is optimized for additive manufacturing, with part divisions and clearances suited for PLA or ABS materials.

Lightweight and Durable Structure: Efficient use of material reduces print time while maintaining strength.

Educational and Research Value: Ideal for demonstrations in biomechanics, robotics, and prosthetic engineering courses.

Customizable Mechanism: Space for actuator placement allows experimentation with servo motors or tendon-based drives.

Applications

This design can be used as a learning tool for students, engineers, and researchers exploring prosthetic limb mechanisms or robotic hand control systems. It’s also valuable for 3D printing enthusiasts who wish to prototype mechanical limbs or experiment with motion studies. The assembly can serve as the foundation for integrating sensors, control circuits, or AI-based gesture recognition systems, paving the way for advanced bionic developments.

Conclusion

The Bionic Palm and Elbow-till-Hand model represents a fusion of mechanical precision and human-inspired design. It bridges the gap between theoretical prosthetic concepts and practical mechanical engineering by offering a fully detailed, modular, and realistic CAD structure. Whether used for demonstration, education, or future robotics research, this model stands as a testament to the evolving capabilities of modern prosthetic and biomechanical design.