Story

Autonomous Sidewalk Delivery Robot

Autonomous Sidewalk Delivery Robot – Prototype and Final Design Development

The rapid growth of e-commerce and last-mile logistics has created a pressing demand for innovative solutions to make deliveries more efficient, sustainable, and cost-effective. To address this challenge, our graduation project focused on designing and prototyping an autonomous delivery robot capable of navigating sidewalks and transporting goods in urban environments.

Design and Development

Our project followed a structured design approach with two main stages:

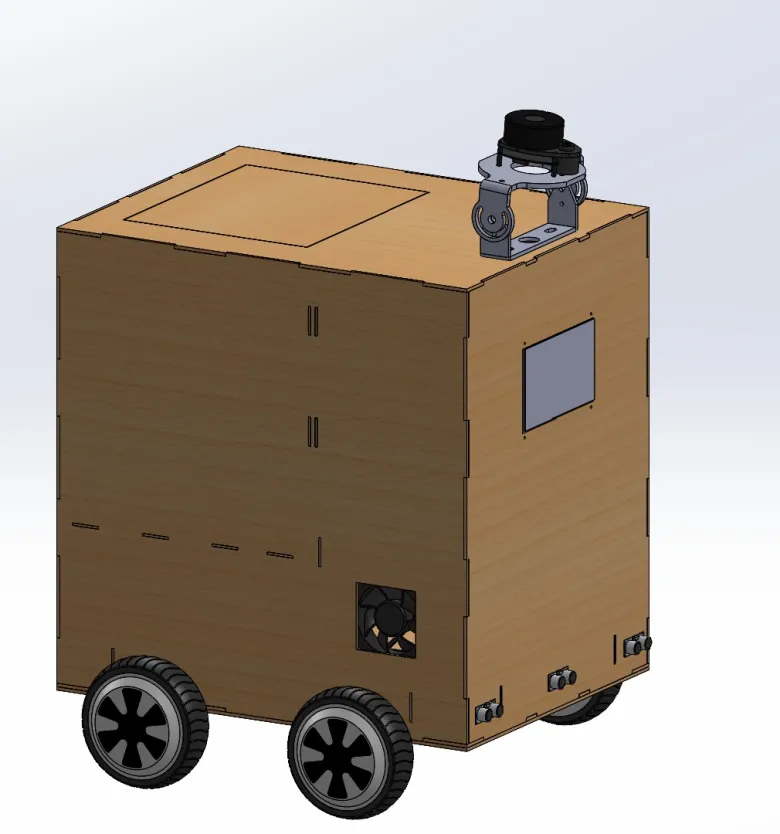

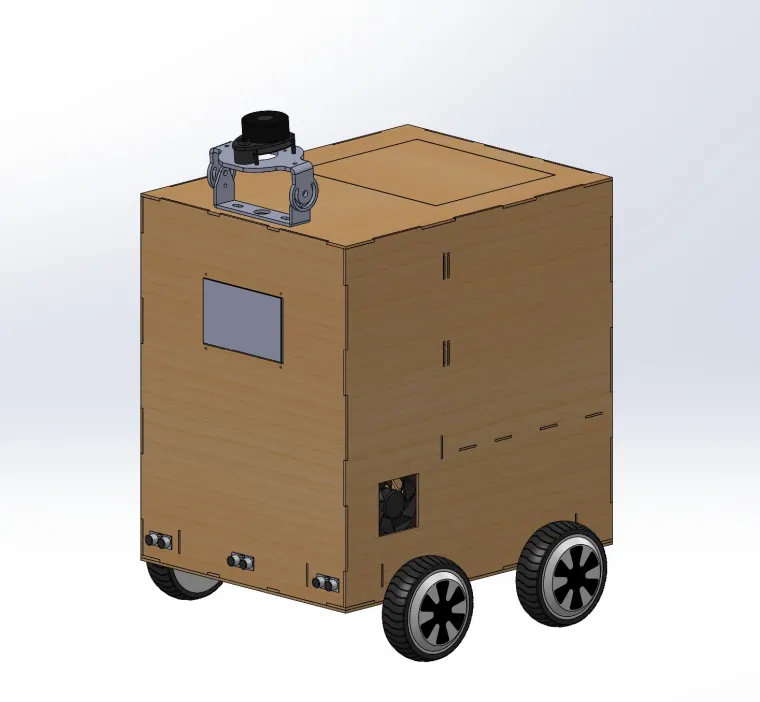

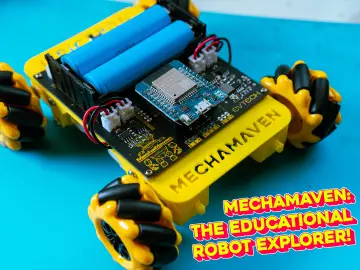

1. MDF Prototype

- Constructed from MDF wood for low cost and ease of manufacturing.

- Dimensions: 56 × 43 × 56 cm.

- Served as a full-scale model to test proportions and verify feasibility before moving to stronger materials.

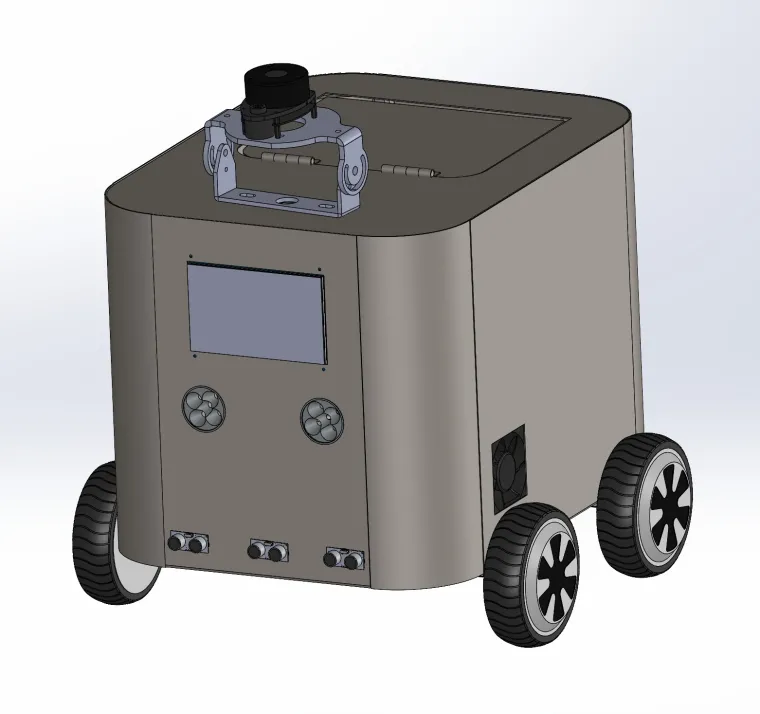

2. Final Steel Design

- Built from steel for durability and real-world applicability.

- Manufactured with a CNC laser cutting machine for high precision.

- Weight: 28 kg, Dimensions: 56 × 43 × 40 cm.

- Equipped with four wheels (16.5 cm diameter) for stability and traction.

Mechanical Structure

The chassis was carefully designed to balance strength with compactness, ensuring that the robot could carry loads while maintaining maneuverability.

- Weight Distribution: The storage compartment is centrally placed to achieve balance during motion.

- Wheel Layout: Four equal wheels provide stability on uneven sidewalks.

- Material Selection: Steel was chosen for strength and durability, while laser cutting ensured precision in assembly.

- Maintenance: The structure allows easy access to internal components, making repairs and upgrades straightforward.

- Safety: Edges were designed with smooth finishes to prevent damage during operation.

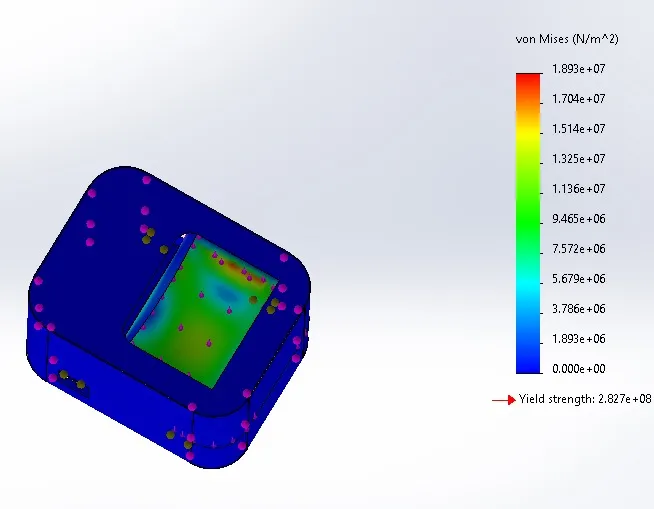

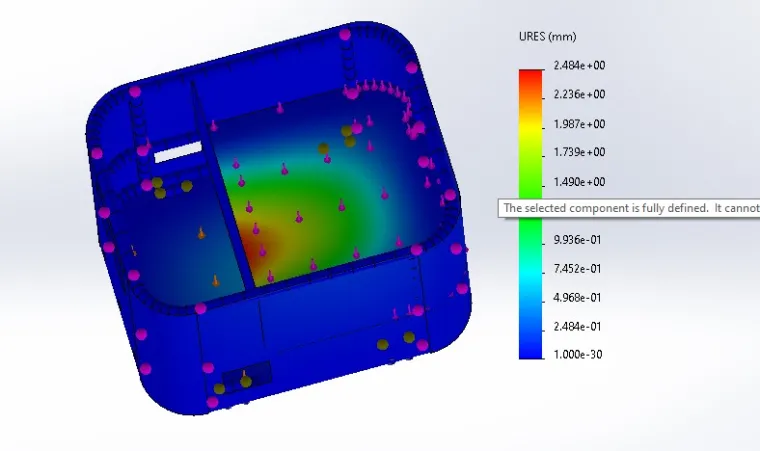

Both stages of development were modeled in SolidWorks, including detailed 3D assemblies, motion analyses, and load simulations. This ensured the mechanical design could withstand real-life stresses and provide reliable performance.

Operation and Working Principle

The operation of the robot is designed to be straightforward and efficient:

1. Initialization – The robot is powered on, loaded with goods, and the delivery destination is set (manually or via an application).

2. Navigation – Movement is managed by drive motors and controlled through an onboard microcontroller.

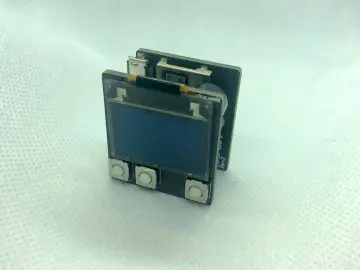

- Ultrasonic sensors detect nearby obstacles to avoid collisions.

- LiDAR maps the surroundings in real time, allowing the robot to adapt to complex urban environments.

- GPS module provides global positioning, enabling accurate path planning and real-time tracking during delivery.

3. Delivery – Upon reaching the target destination, the robot stops safely and allows the recipient to access the goods.

The integration of Ultrasonic, LiDAR, and GPS ensures precise navigation, reliable obstacle avoidance, and efficient delivery routing.

IoT Integration Potential

While the prototype focuses mainly on mechanical and operational aspects, the design strongly supports future integration with IoT technologies. By adding modules such as LoRa or Wi-Fi, the robot could achieve:

- GPS-based tracking and route optimization.

- Real-time monitoring and cloud connectivity.

- Seamless integration with delivery applications.

Conclusion

The Autonomous Sidewalk Delivery Robot demonstrates the importance of iterative design, moving from an MDF prototype to a durable steel final version. The project strengthened our skills in mechanical design, simulation, material selection, and precision manufacturing.

With its solid mechanical foundation, integration of Ultrasonic sensors, LiDAR, and GPS, and potential for IoT expansion, the robot provides a practical solution for last-mile delivery. Future developments can expand its autonomy, making it a valuable tool in e-commerce, food delivery, and urban logistics.

Sharing this project with the community is an invitation to innovate, collaborate, and push forward smarter and more sustainable delivery systems.