Story

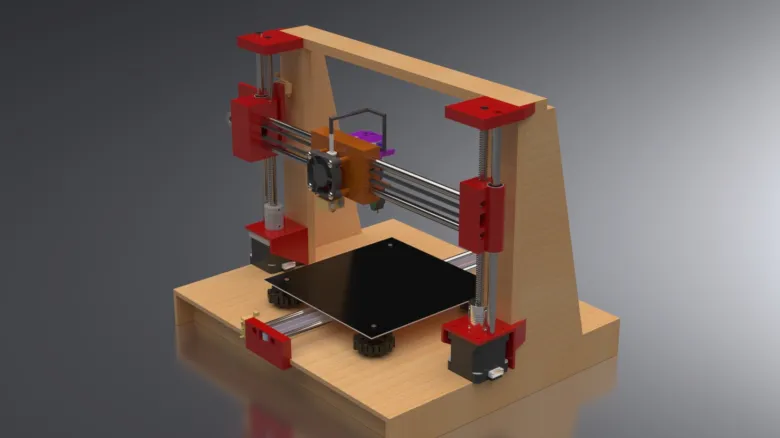

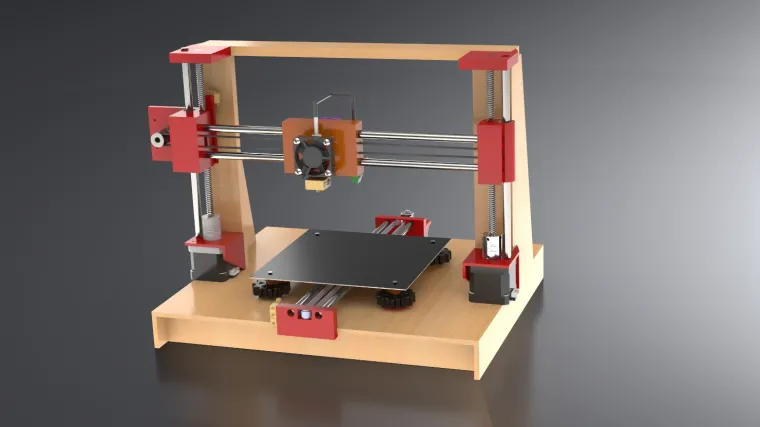

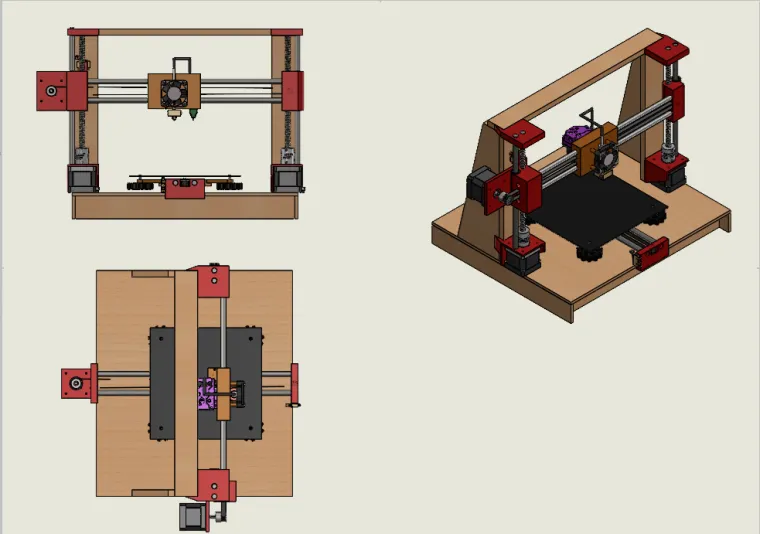

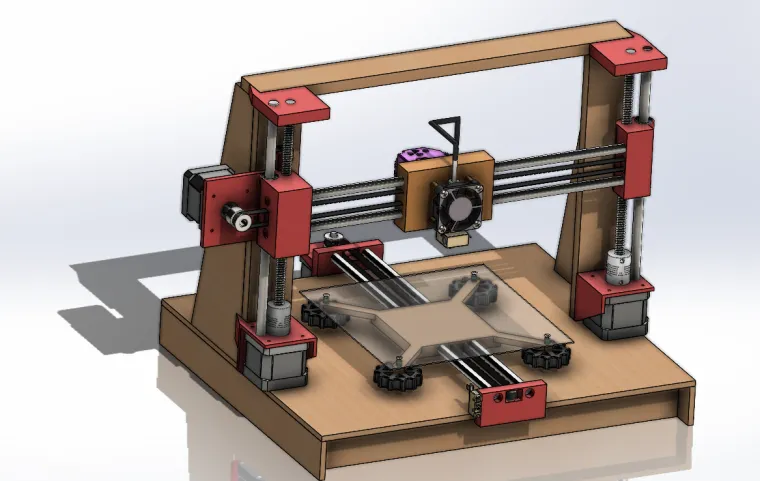

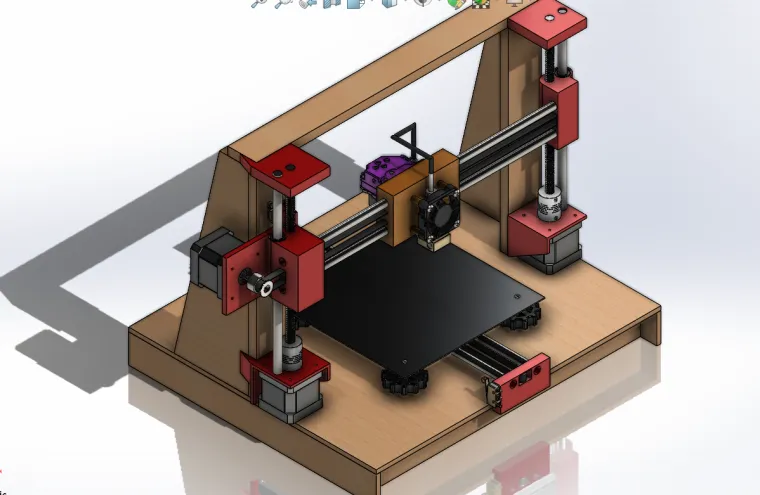

This project presents a complete DIY 3D printer that I designed and modeled entirely in SolidWorks 2025. It is inspired by open-source CoreXY and Cartesian-style architectures but developed as an independent digital model to demonstrate mechanical design, motion analysis, and mechatronic integration in one cohesive assembly. The goal of this project is to explore how a modern 3D printer can be designed from scratch with realistic geometry, proper mechanical constraints, and accurate spatial organization between all moving components. The project focuses on structural stability, motion accuracy, and accessibility for makers and engineers who want to learn the mechanical side of 3D printing.

The 3D printer is composed of a modular aluminum frame made from 2020 extrusion profiles, connected using corner brackets and fasteners for maximum rigidity. The frame was modeled with precise dimensional tolerances and parameter-driven references to allow for future scaling or adjustment of the build volume. The printer uses a CoreXY-style motion system for the X and Y axes, which provides high-speed movement and reduced moving mass compared to conventional Cartesian setups. Two NEMA 17 stepper motors drive the GT2 belt system, with idler pulleys and tensioners modeled for realistic belt routing. Linear rails are used for the X, Y, and Z axes to ensure smooth and stable motion, and every bearing block, pulley, and screw is modeled with physical accuracy.

The Z-axis is supported by dual lead screws connected through flexible couplers to the stepper motors. This dual-screw system eliminates tilting of the print bed and improves vertical precision. The bed plate is modeled as an aluminum base with a heater and glass surface representation, mounted with spring-loaded adjustment screws for manual or assisted leveling. To simulate modern automation features, a BLTouch-style sensor is included in the model near the hotend. This sensor is commonly used in real printers for automatic bed leveling and demonstrates how feedback sensors can be integrated into mechanical design.

The hotend and extruder are designed as a compact, direct-drive unit. It includes the E3D-style hotend assembly with a heat sink, heater block, thermistor slot, nozzle, and cooling fan. The model also includes the filament path and mounting plate for the extruder motor. The design is fully parametric, meaning that dimensions such as print area, rod spacing, and motor positioning can be modified without breaking the assembly references. All subassemblies (frame, motion system, extruder, and electronics) are organized for clarity and modification flexibility.

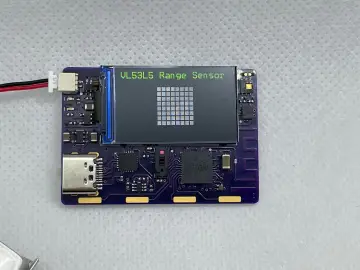

The electronics layout includes placeholders for a controller board, stepper drivers, endstops, and power supply. Cable paths and fan locations are modeled to visualize how wiring and airflow interact with the rest of the system. The entire design was verified through SolidWorks Motion Study to ensure that the axes can move freely without collisions or interference between parts. This process helped simulate real-world mechanical performance and verify the design’s kinematic integrity before physical prototyping.

The software tools used for this project were SolidWorks 2025 for the main design, SolidWorks Visualize for rendering and presentation, and AutoCAD Electrical for schematic layout planning. Reference dimensions for certain mechanical standards, such as GT2 belts and linear rails, were checked using open-source data and slicer software like Cura and PrusaSlicer. This combination of tools allowed the project to integrate mechanical realism with visual clarity for documentation and presentation.

This project represents a comprehensive learning exercise in mechanical system design, parameter management, and motion study. It provides an educational platform for students and engineers who want to understand how 3D printers work structurally before dealing with electronics and firmware. By making the model open and modifiable, others can learn from it, improve it, or adapt it for their own experimental printers. The ultimate goal is to share a digital twin that captures the essence of a functional 3D printer while being detailed enough for fabrication or further automation integration. This project demonstrates how digital engineering can bridge the gap between conceptual learning and real-world manufacturing design.