Story

Hand Blender for Electromechanical and Automation Competition

Project Description and Design Overview

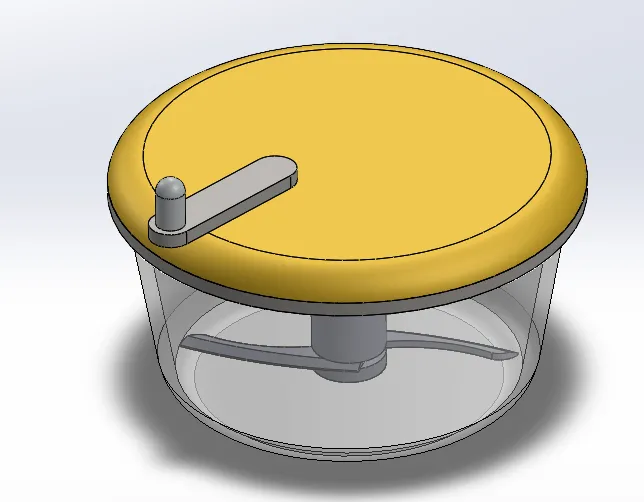

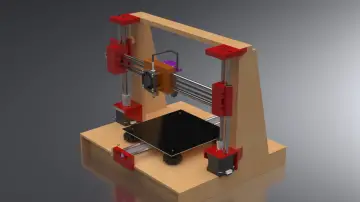

This project presents a hand blender designed and modeled in SolidWorks, created specifically for participation in an Electromechanical and Automation competition. The primary goal of this design is to demonstrate how a simple mechanical system can successfully perform its intended function while providing high efficiency and significant energy savings. Although the blender is based on a basic mechanism consisting of only two gears, it achieves effective mixing performance and stands as a clear example of how simplicity in design can lead to reliability, durability, and sustainability.

The blender operates using a two-gear transmission system that transfers rotational motion from the motor to the blade assembly. This simple gear mechanism was intentionally selected to reduce mechanical complexity, minimize friction losses, and improve overall system efficiency. By optimizing the gear ratio, the system ensures that sufficient torque is delivered to the blades even at low motor speeds. As a result, the blender can mix dense or viscous materials efficiently without requiring high power consumption, which directly contributes to electric energy savings.

Mechanical Structure and Working Principle

The core of the blender consists of a compact motor, two intermeshing gears, a central shaft, and a dual-blade mixing system. When the motor is activated, it rotates the primary gear, which in turn drives the secondary gear connected to the blade shaft. This controlled transmission of motion allows the blades to rotate at an optimal speed, ensuring consistent and uniform mixing of ingredients. The smooth synchronization between the gears prevents sudden torque fluctuations, thereby increasing the lifespan of both the motor and mechanical components.

The simplicity of the two-gear system also reduces the number of parts required, making the blender easier to manufacture, assemble, and maintain. Fewer components mean lower production costs and reduced chances of mechanical failure. This design approach aligns with modern engineering trends that emphasize minimalism and functionality without compromising performance.

Energy Efficiency and Sustainability

One of the most significant advantages of this blender design is its focus on energy efficiency. Traditional blenders often rely on high-speed motors that consume large amounts of electricity. In contrast, this model operates effectively at lower speeds due to the optimized torque transfer provided by the gear mechanism. This results in reduced power demand while still achieving the desired mixing performance.

The reduced energy consumption not only lowers operational costs but also contributes to environmental sustainability. By minimizing unnecessary power usage, this design supports global efforts to reduce carbon footprints and promote eco-friendly engineering solutions. This makes the blender a practical and responsible choice for both domestic and small-scale commercial use.

Automation and Control Potential

Although the current design focuses on mechanical simplicity, it is fully compatible with automation systems. The blender can be integrated with speed controllers, sensors, and programmable control units to allow for variable speed adjustment, automated mixing cycles, and safety features such as overload protection and auto shut-off. This flexibility demonstrates its potential for future technological enhancements and smart kitchen applications.

From an educational perspective, this project serves as an excellent example of interdisciplinary engineering, combining principles of mechanical design, electromechanics, and automation. It clearly illustrates how motion transfer, torque control, and energy optimization can be achieved through thoughtful design and simulation tools such as SolidWorks.

Conclusion

In conclusion, this hand blender represents a successful implementation of a simple yet effective electromechanical system. Despite relying on a basic two-gear mechanism, it performs its function efficiently while ensuring energy savings and mechanical reliability. The design highlights the importance of simplicity, optimization, and sustainability in modern engineering.

This project not only fulfills the functional requirements of a blender but also demonstrates innovation through intelligent design choices. It proves that even minimal mechanical systems can achieve high performance when supported by proper engineering analysis and digital modeling. As such, this blender design is a strong candidate for the Electromechanical and Automation competition, showcasing both technical competence and creative problem-solving.