Story

Hydraulic Transmission

As part of my mechanical engineering training, I worked on the study and design of a hydraulic scissor lift with the following specifications:

▪️ Capacity: 300 kg

▪️ Maximum height: 10 m

▪️ Lifting speed: 0.15 m/s

▪️ Lowering speed: 0.2 m/s

I. Functional Analysis

• FC0: Safely lift and lower a 300 kg load.

• Constraints: stability, speed control, operator safety, energy efficiency.

II. Chart of Purpose (Bête à cornes)

• Why? Safe work at height (access, maintenance, installation).

• What? People, tools, or loads ≤ 300 kg.

• Environment? Indoor workshop/site mainly, occasional outdoor use (wind, dust), stable ground.

III. Service Functions (FS)

• FS1 – Lift the load up to 10 m.

• FS2 – Hold the load without sagging.

• FS3 – Lower the load in a controlled manner.

• FS4 – Fine positioning (intermediate stops, smooth restarts).

• FS5 – Inform/alert (indicators, alarms).

IV. External Interactions (Octopus Diagram)

• Payload ↔ stability, center of gravity.

• Ground/support ↔ bearing capacity, flatness.

• Operator ↔ controls, safety.

• Power supply ↔ electrical/hydraulic.

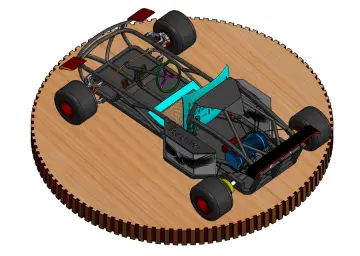

▪️ Modeling & Simulation in SolidWorks:

I designed the system in 3D and validated its behavior through simulation.

This project allowed me to turn functional analysis, dimensioning, and virtual validation into a concrete technical solution.