Story

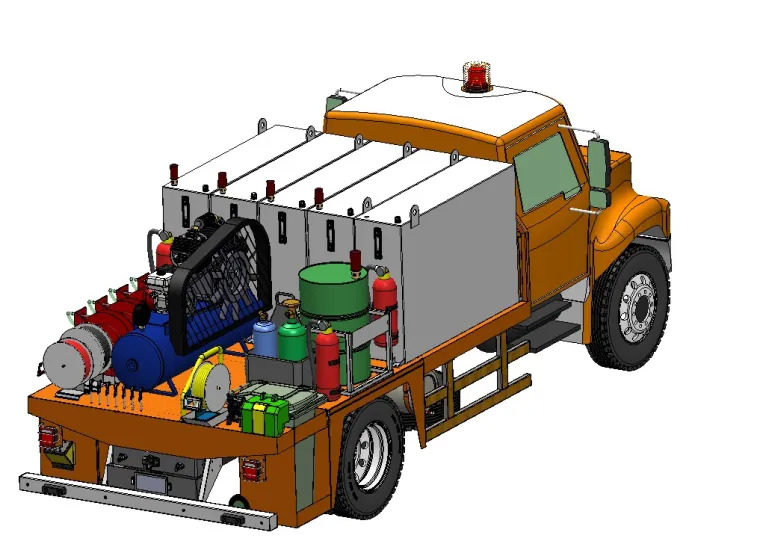

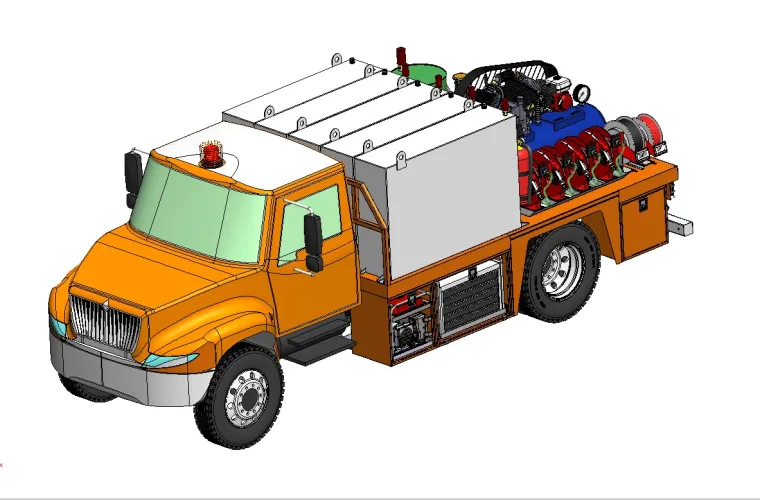

🔧🚛 Maintenance & Lube Truck – Mechanical CAD Design (GAD)

🏷️ Project Category

⚙️ Mechanical Design | Industrial Vehicle | Maintenance Equipment

📌 Project Overview

This project showcases a complete Mechanical CAD & GAD design of a Maintenance & Lube Truck 🚛🛢️, developed for on-site servicing and lubrication of heavy machinery used in construction 🏗️, mining ⛏️, oil & gas 🛢️, and industrial operations.

The truck is designed as a mobile maintenance workshop, capable of supplying multiple grades of oils, grease, compressed air, welding support, and safety systems directly in the field 🌍.

The focus of the design is on practical usability, safety 🦺, proper weight distribution ⚖️, and ease of maintenance.

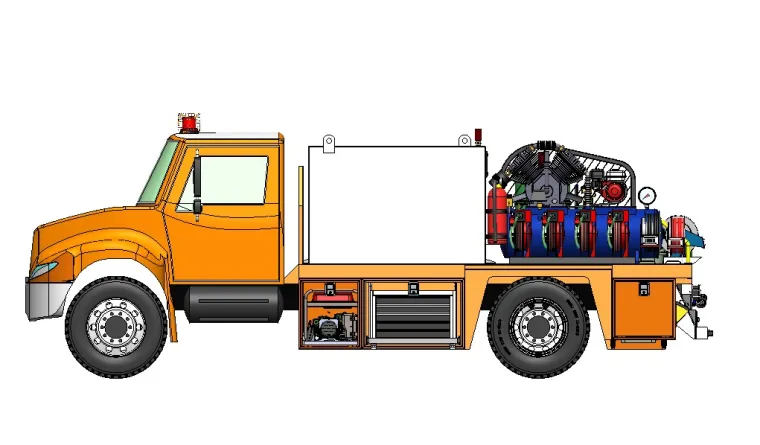

🚚 Base Vehicle & Chassis

- Chassis: International 4300 SBA 4×2

- Drive: 4×2

- Application: Medium-duty industrial service truck

- Design Standard: First Angle Projection 📐

- Units: All dimensions in millimetres (mm)

This chassis was selected for its strong frame 💪, reliability, and suitability for industrial upfitting.

🛢️ Lubrication & Fluid Systems

The truck is equipped with multiple dedicated fluid tanks, designed for safe storage and controlled dispensing:

- 🔹 Hydraulic Oil Tank – 1000 L

- 🔹 Engine Oil Tank – 1000 L

- 🔹 Gear Oil Tank (90W) – 1000 L

- 🔹 Gear Oil Tank (140W) – 1000 L

- 🔹 Waste Oil Recovery Tank – 1000 L

- 🔹 Grease Drum – 180 kg

Each system includes:

- ⚙️ Air-operated oil pumps

- 🧴 High-ratio grease pump (60:1)

- 📊 Digital oil dispensers

- 🧵 Hose reels with industrial hoses

This allows clean, accurate, and efficient lubrication service in field conditions.

🔩🧰 Maintenance & Utility Equipment

To function as a self-sufficient mobile workshop, the design integrates:

- 🔧 Diesel air compressor (200 L)

- 🔥 Diesel welding set (160 Amps)

- 🔥 Portable oxy-acetylene cutting & welding kit

- ⚡ Generator set (7 kVA)

- 🧰 Heavy-duty tool boxes & trays

- 🛠️ 406-piece professional tool kit

All equipment is positioned for easy access and safe operation.

🦺🧯 Safety & Emergency Features

Safety is a key design priority. The truck includes:

- 🧯 ABC fire extinguishers (10 kg & 2 kg)

- 🛢️ 120-liter hydrocarbon spill containment kit

- 🚿 16-gallon emergency eye wash station

- 🛑 Wheel chocks & rear bumper protection

- 🚨 Beacon light & backup sensors

- 🧼 Spill kit tray and drainage provisions

These features help ensure safe maintenance operations in harsh industrial environments.

🏗️ Structural & Layout Design

- 🧱 Reinforced sub-frame mounted on chassis

- ⚖️ Optimized weight distribution & center of gravity

- 📦 Separate compartments for oils, tools, and power equipment

- 💧 Drain holes at cabinet bottoms

- 🔄 Rounded edges to avoid sharp corners

The layout is optimized for service efficiency, stability, and operator safety.

💻 CAD & Documentation

- 📐 Detailed General Arrangement Drawing (GAD)

- 📋 Complete Bill of Materials (40+ components)

- 🖼️ Front, rear, side & top views

- 🎨 Realistic industrial 3D renderings

This project represents a fabrication-ready mechanical design concept.

🏭 Applications

- ⛏️ Mining equipment maintenance

- 🏗️ Construction machinery servicing

- 🚛 Fleet maintenance operations

- 🛢️ Oil & gas field services

- 🏭 Industrial plants & infrastructure projects

👤 Designer Introduction

Hi, I’m Sohail Rabbani 👋

I’m a Mechanical design Engineer specializing in industrial vehicles 🚚, service trucks, and heavy-duty mechanical layouts. This project reflects my approach toward practical engineering, safety-focused design, and real-world usability.

✅ Conclusion

The Maintenance & Lube Truck 🚛🛢️ is a complete mechanical engineering solution, integrating lubrication systems, maintenance tools, safety equipment, and structural design into a single mobile platform.

Due to the large file size, the project has been uploaded separately. Kindly download the files and open them using SolidWorks 2025 for full viewing and evaluation. Here is wetranfer link for our CAD file MAIN