Story

3D-Printed Modular 5-Inch Quadcopter Frame

Abstract

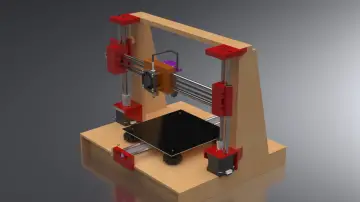

The project demonstrates how a structurally sound, lightweight, and repairable modular 5-inch quadcopter drone frame can be designed using parametric CAD tools and manufactured using commonly available thermoplastics such as PETG and PA6-CF. The resulting design includes modular arms, support for standard FPV electronics, optional foldable mechanisms, and detailed technical documentation, making it suitable both for practical flying and as an educational engineering project.

Introduction

Quadcopters in the 5-inch class are widely used in FPV freestyle, racing, and experimental UAV projects due to their balance between agility, efficiency, and payload capacity. Traditionally, such frames are manufactured from carbon fiber composites, which offer excellent stiffness-to-weight ratios but are costly and difficult to repair.

With the increasing availability of high-performance 3D printing materials and desktop FDM printers, it has become feasible to design drone frames that are:

-

inexpensive,

-

rapidly manufacturable,

-

easily repairable,

-

and fully customizable.

The goal of this project was to design a complete, printable quadcopter frame, without relying on carbon fiber parts, while maintaining adequate mechanical strength and flight suitability.

Design Requirements

The main design requirements were defined as follows:

-

Frame size: 5-inch propellers

-

Configuration: Quad X

-

Motor-to-motor distance: 220 mm

-

Electronics compatibility:

-

Flight controller: 30.5 × 30.5 mm (M3)

-

4-in-1 ESC

-

Standard 22xx motors (16 × 19 mm mounting pattern)

-

-

Fasteners: M3 screws throughout

-

Manufacturing method: FDM 3D printing

-

Materials: PETG (baseline), PA6 / PA6-CF (recommended)

-

Repairability: Modular arms, replaceable components

Mechanical Architecture

The frame is composed of several independent components:

-

Four modular arms

-

A bottom plate (main structural element)

-

A top plate

-

Printed standoffs

-

FPV camera canopy

-

Optional foldable arm hinges

-

Optional metal threaded inserts (heat-set)

This modular approach allows damaged arms to be replaced individually, significantly reducing maintenance costs and downtime after crashes.

Stress concentrations were minimized by avoiding sharp internal corners and by using smooth transitions (fillets and hulls) between structural features.

Material Optimization

Two primary material classes were considered:

PETG

-

Easy to print

-

Good layer adhesion

-

Suitable for beginners

-

Adequate for moderate flight loads

PA6 / PA6-CF (Carbon Fiber Reinforced Nylon)

-

High toughness and fatigue resistance

-

Excellent vibration damping

-

Significantly higher impact resistance

-

Recommended for aggressive freestyle flying

For PA-CF, design modifications included thicker arms, increased wall counts, and compatibility with heat-set metal inserts to prevent thread wear.

Assembly Process

-

Install metal inserts (if used)

-

Attach arms to the bottom plate

-

Mount ESC and flight controller

-

Install standoffs

-

Attach top plate

-

Mount FPV camera and canopy

-

Install motors and wiring

The assembly requires only standard M3 hardware and basic hand tools.

Conclusion

This project demonstrates that a fully 3D-printed quadcopter frame can be a viable, practical alternative to traditional composite designs. By combining parametric CAD, modern filament materials, and thoughtful mechanical design, it is possible to create a robust, customizable, and accessible drone platform.

The resulting frame offers:

-

High modularity

-

Competitive durability for a printed design

-

Low production cost

-

Rapid iteration capability

While it does not fully replace carbon fiber frames in professional racing, it performs exceptionally well for freestyle flying, experimentation, education, and rapid prototyping.

The complete design package—including CAD files, STL exports, and technical documentation—is suitable for open-source distribution and further community development.