Story

1. Introduction

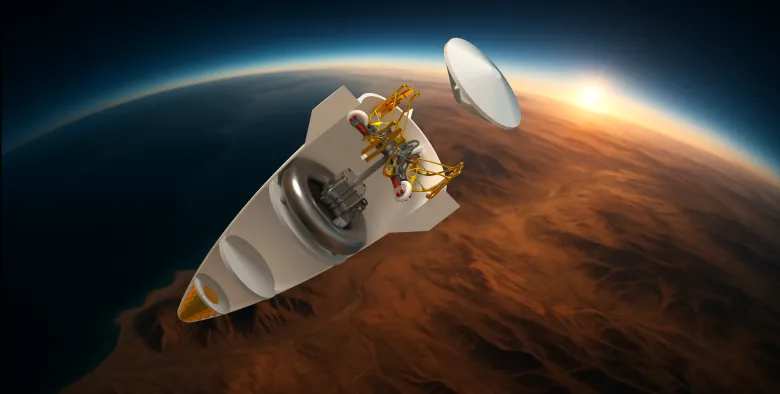

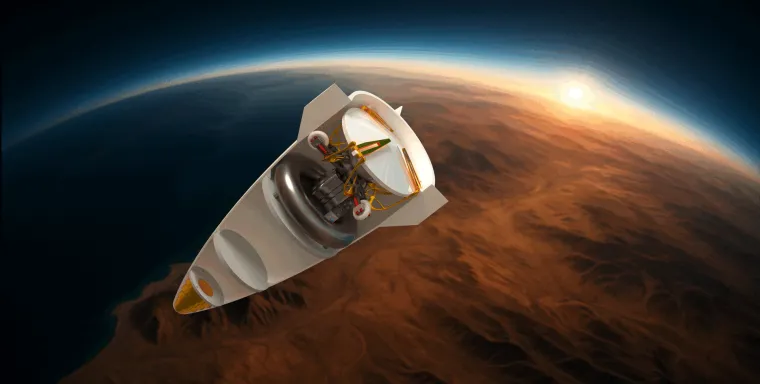

The SPEED (Suborbital Particle Ejection Experiment Demonstrator) challenge seeks innovative concepts for an ejection mechanism capable of reliably deploying a scientific payload from a suborbital launch system during free-fall. The goal is to separate the test capsule at high altitude (around 27 km), ensuring minimal disturbance, a clean departure from the carrier body, and a consistent initial velocity all within the constraints of mass, simplicity, and mechanical robustness.

In response to this challenge, my research has focused on developing a compact, modular pneumatic ejection system. Rather than relying on mechanical springs or explosive triggers, I explored the potential of using the natural pressure differential between ground level and high-altitude conditions to store and release energy. The resulting design features a passive air reservoir, a centrally driven piston, and a low-friction guidance system, offering both precise control and strong repeatability while maintaining low mass and mechanical simplicity. This solution aims to balance engineering efficiency with mission-critical reliability, using easily manufacturable components and straightforward integration logic.

2. Initial Hypotheses & Physical Principles

The concept began with a simple question: could the natural drop in atmospheric pressure with altitude be used as an energy source? Rather than carrying pre-compressed gas or relying on mechanical springs, I hypothesized that sealing ambient air at ground level inside a reservoir could create a usable pressure differential at high altitude. At 27 km, the ambient pressure drops to about 2.4 kPa, while air sealed at 1 bar on the ground remains compressed by comparison. This pressure difference can drive a piston, enabling a clean, repeatable ejection. Using thermodynamic assumptions (ideal gas behavior, isothermal expansion), I estimated the available force, energy, and acceleration. This led to a model where pneumatic force is not just viable, but potentially simpler, lighter, and more modular than the traditional spring-based approach. The idea leverages environmental conditions instead of resisting them, turning a constraint into a design opportunity.

3. Exploratory Phase & Creative Method

The project began with a hands-on approach: physical prototyping using LEGO Technic to explore motion, retention, and synchronized release mechanisms. These mockups helped visualize mechanical constraints early, especially how to combine ejection and unlocking in a single, efficient motion. I then iterated between rough sketches and digital tools, testing layout concepts and geometric behaviors. Throughout the process, I integrated AI assistance to simulate forces, estimate parameters, and challenge assumptions a form of hybrid thinking between human intuition and computational rigor. This exploration confirmed that a pneumatic system could be both structurally simple and functionally elegant. The method emphasized low-fidelity experimentation before committing to CAD, allowing creativity to lead engineering not the other way around.

4. 3D Design & Digital Prototyping

Once the concept was validated through mockups, I transitioned to full 3D modeling to integrate all components into a compact, manufacturable design. The carriage was modeled with a truss-like structure to balance strength and lightness, resulting in a chassis weighing just 190 g. A central piston interface was designed to receive force symmetrically, while three articulated arms with spring-loaded wheels ensured stable, centered vertical motion. The design accounted for internal launcher geometry and allowed for tool-free assembly. CAD also enabled accurate volume and mass calculations, mechanical clearances, and later, stress analysis. By building the system virtually, I could simulate tolerances, pressure routing, and integration without needing a physical prototype. This digital-first approach laid the foundation for real-world feasibility.

Integrated Release Mechanism The release and ejection functions are fully integrated into a single mechanical motion. As the piston pushes the carriage upwards, a mechanical interface unlocks the capsule from its retention point avoiding the need for separate actuators, servos, or cutters. This design significantly reduces failure points, simplifies assembly, and ensures timing precision between unlock and ejection.

5. Engineering Calculations & Static Simulations

The design was dimensioned from first principles. To meet the required ejection velocity of 5 m/s for a 1.3 kg capsule, I calculated the kinetic energy needed: E = ½mv² ≈ 16.25 J. Using a piston with a 50 mm diameter and a stroke of 110 mm, I estimated the available pneumatic force based on the altitude pressure differential. At 27 km, a sealed 1 bar tank provides a net pressure of ~76 kPa, giving a pushing force of ≈149 N. The energy delivered by this force over the piston stroke confirms the target velocity is achievable.

For structural validation, I performed static analysis on the carriage using a load case where 149 N is applied vertically, simulating the piston’s force. Additionally, each of the three guidance wheels applies a 7.45 N radial preload, modeled as lateral constraints. The total radial force (~22.35 N) ensures self-centering during motion. Material assumptions (PLA or aluminum) were used to verify safety margins under stress.

All calculations were supported by AI-augmented iteration to explore trade-offs between energy storage, pressure, stroke length, and part thickness ensuring performance with minimal mass and volume.

6. Technical Assembly – Pneumatic Architecture

The pneumatic system is designed around simplicity and modularity. A sealed air reservoir pressurized at ground level is connected to a 3/2 solenoid valve (Festo VUVS-L10-M32C) via standard 6 mm push-in tubing. The valve is electrically triggered by a microcontroller through a low-side MOSFET switch, allowing remote activation. Upon command, the valve delivers compressed air to a compact 50 mm piston (Festo ADVU-50-100), which pushes the ejection carriage along a vertical guide. Three QSML-G1/8-6-I elbow fittings route the airflow with minimal pressure loss. The system uses common Festo components for quick assembly, repeatability, and off-the-shelf maintenance. A PID diagram and cable routing layout ensure clear integration into the test platform.

7. Comparison with NASA’s Spring-Based System

NASA’s baseline system for the SPEED project uses a mechanical ejection mechanism driven by heavy compression springs, held in place with a vectran cord and released via hot-wire cutter. This method is reliable and robust, but inherently one-shot and mechanically intense: three springs provide a combined force of over 1800 N to achieve the required 5 m/s ejection velocity. However, the total weight of the spring assembly including the cord, cutter, structural restraints and guide rails is estimated at around 740 g.

In contrast, the pneumatic solution proposed here achieves the same velocity target with less than 150 N of pushing force, using a pressure differential of just 0.75 bar. The total system mass (carriage, piston, valve, and tubing) is estimated at ~630 g, already lighter than the spring setup and more importantly, it’s modular and tunable.

By adjusting the initial pressure inside the sealed air tank (from 1 to 5 bar), the ejection velocity can be varied from 5 to over 11 m/s, allowing mission-specific tuning. This makes it ideal for future test variations or multi-altitude campaigns. Unlike springs, the pneumatic system is not "all or nothing" — it offers smooth control, repeatable triggering, and a cleaner integration with electronics.

Safe Ground Handling, the SPL system remains entirely unpressurized and untensioned during all ground operations.Since the air reservoir is sealed at ambient pressure and no spring or actuator is preloaded, the mechanism is completely safe to transport, assemble, and manipulate. This removes the need for special tooling, ESD protection, or pressure certifications prior to launch preparation.

Additionally, the pneumatic method avoids fatigue, cord failure, or hot-wire uncertainties. It allows safe testing and re-arming between missions. For compact platforms requiring modularity, remote activation, and low maintenance, the pneumatic design is not only lighter, it's smarter.

8. Conclusion & Perspectives

This project demonstrates that a lightweight, low-pressure pneumatic ejection system can meet the performance targets of the SPEED challenge with simplicity, modularity, and robustness. Starting from first principles and physical constraints, a complete solution was designed: from conceptual sketches and LEGO mockups to 3D modeling, dimensioning, and technical validation through static simulations.

All components were selected based on manufacturability, accessibility, and integration potential. The use of sealed ambient air as an energy source — rather than springs or high-pressure gas — shows promise for modular testing environments and simplified flight readiness. The ability to tune the system’s performance by adjusting the pressure offers flexibility rarely found in purely mechanical designs.

However, while the engineering simulations provide consistent, traceable results, they remain only a version of the possible. Real-world conditions — including temperature fluctuations, air leaks, mechanical tolerances, and launch dynamics — can only be validated through physical testing. This is where design becomes reality, and theory must prove itself.

Nonetheless, this exercise illustrates how a functional, testable, and adaptable system can emerge from first-principle reasoning, accessible tools, and iterative refinement. The approach highlights the power of combining intuition, digital prototyping, and collaborative intelligence, all while staying grounded in engineering logic. Ultimately, the sky is not the limit, it's the testing ground.