Story

If you want to teach people a new way of thinking, don't try to teach them. Instead, give them a tool that will lead them to new thoughts.

(Richard Buckminster Fuller)

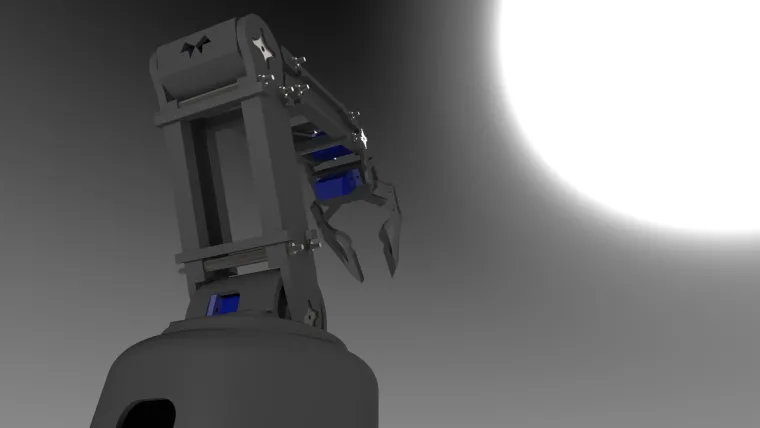

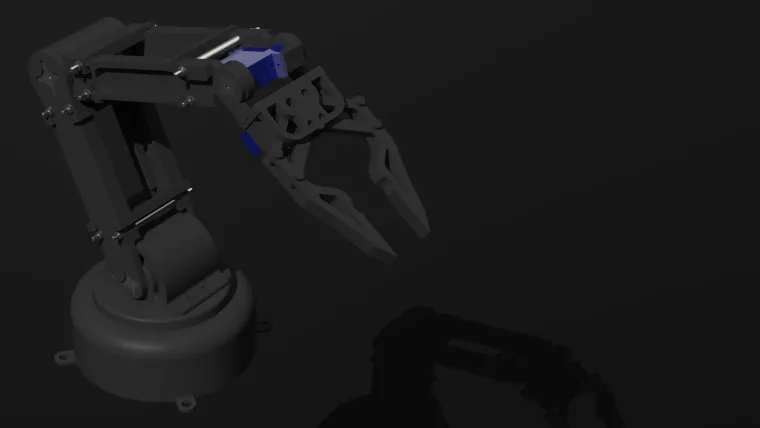

In today's world, robotics and mechatronics are becoming increasingly popular, but for many beginners, entering this field can be challenging due to the abundance of technical details and the high cost of equipment. To address this issue, the Omega 4-axis robot manipulator has been developed as a simple and affordable solution for children, teenagers, and anyone interested in exploring robotics without extensive theoretical knowledge.

The main principles of the project are simplicity and accessibility

The main goal of “Omega” is to simplify robotics so much to allow anyone to build and program their first robot without unnecessary complications. Unlike industrial manipulators that require in-depth knowledge of programming and mechanics, this project is reduced to a minimum of sensors, parts and electronics, making it ideal for educational purposes.

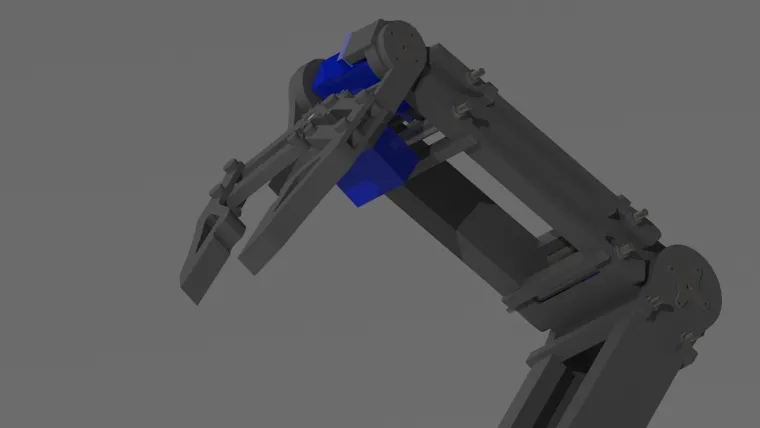

The robot's design is optimized for 3D printing, which significantly reduces its cost and allows users to independently manufacture the robot arm's components. During the development process, special attention was paid to minimizing the consumption of plastic without compromising its durability and functionality. This not only makes production more cost-effective but also reduces the environmental impact, which is crucial in today's increasingly focused on sustainability.

Possibility of modification and flexibility of materials

“Omega” can be printed from different types of plastic (PLA, ABS, PETG, nylon), which allows it to be adapted to different conditions and tasks.

This approach not only reduces the cost of assembly, but also encourages experimentation – users can themselves modify parts, change the design and even create their own versions of the robot.

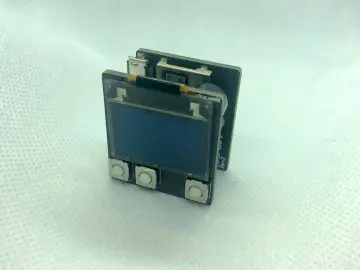

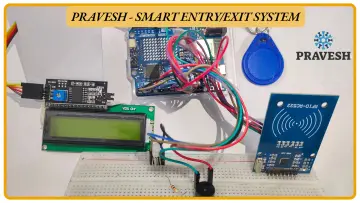

Electronic platform

The Omega is based on Arduino, one of the most popular platforms for beginner robotics. All components (servos, divers, sensors) are connected using jumpers, which simplifies assembly and does not require soldering.

For those who want to delve deeper into the project, it is possible to switch to ESP boards. This opens up access to Wi-Fi and Bluetooth control and more complex automation scenarios.

Intuitive Android app

To further simplify interaction with the robot, a special application with a friendly interface has been developed. It has the following features:

• Set simple movements using sliders.

• Create sequences of actions (scenarios).

• Save and load programs.

• Control the robot via Wi-Fi

This allows beginners to start programming immediately without having to understand complex code.

The main idea of the project

Omega is not an innovative or high–tech project. His main task is to make mistakes. After all, it is only through mistakes that a person can grow and make mistakes. Unlike expensive industrial solutions, where every mistake can cost a lot of money, the cost of failure is minimal here: you can reprint a part, reprogram a board, or change the code without serious consequences.

This approach removes the psychological barrier for beginners and encourages experimentation. After all, it is through trial and error that a true understanding of mechanics and programming is born.

Conclusion

The Omega robot manipulator is an ideal starting point for those who want to learn about robotics in an easy and accessible way. With its 3D printing, simple assembly, and intuitive controls, it is an excellent educational tool for schools, clubs, and home experiments.

This project is not about high technology, but rather about education and sustainability. It demonstrates that learning about robotics does not require expensive components; it only requires a willingness to learn and experiment.

With Omega, anyone can take their first step into the world of robots – easily, cheaply, and without fear of making mistakes.