Story

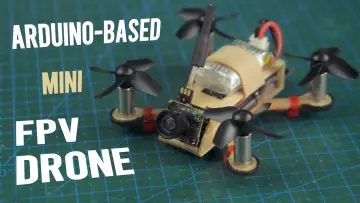

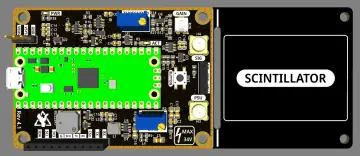

Designing and fabricating a stack holder for a Pixhawk 2.4.8 flight controller and a Raspberry Pi 4 on a QAV250 racing drone frame is a practical approach for integrating advanced flight control with onboard computing. The QAV250 is a compact and lightweight carbon fiber quadcopter frame that provides excellent rigidity, making it an ideal base for combining an autopilot with an additional companion computer for autonomous navigation, computer vision, or telemetry processing.

Purpose of the Stack Holder

The main goal of the stack holder is to secure both the Pixhawk 2.4.8 and the Raspberry Pi 4 in a layered configuration while maintaining accessibility, stability, and vibration isolation. The holder ensures that sensitive electronic components are protected during high-speed maneuvers, landings, and minor crashes. Since the QAV250 is compact, the stack holder must optimize vertical space while keeping the center of gravity low. Heat dissipation for the Pi 4 is also a concern, so ventilation gaps or mounting provisions for a heatsink/fan should be included.

Design Considerations

Size and Clearance:

The Pixhawk 2.4.8 typically measures about 50 × 80 mm, while the Raspberry Pi 4 measures 56 × 85 mm. The stack holder must provide mounting holes aligned with both components while leaving clearance for connectors, SD card slots, and USB ports.

Layered Assembly:

Using M3 heat-set threaded inserts and nylon or aluminum standoffs allows the two boards to be stacked securely. A recommended setup is Pixhawk at the bottom (closest to the drone’s center of gravity) and Raspberry Pi 4 above it, ensuring clean wiring for telemetry and power distribution.

Weight Distribution:

Since drones are highly sensitive to weight, the design must balance strength and lightweight features. Excess plastic or bulky walls should be avoided, and honeycomb or lattice structures can be integrated for strength without mass penalties.

Vibration Dampening:

The Pixhawk is sensitive to vibrations from motors and propellers. Incorporating rubber grommets or TPU vibration-dampening pads in the design ensures more reliable sensor readings.

Accessibility:

Cutouts for Pi 4’s micro-HDMI, USB, and Ethernet ports should be included if they are required during operation. Similarly, access to Pixhawk’s I/O ports for GPS, telemetry, and ESC signal wires should not be blocked.

Best Filament Choice

The choice of filament material for 3D printing the stack holder is critical, as it affects the balance of strength, durability, and weight. The main candidates are:

PLA+ (Polylactic Acid Plus):

PLA+ is easy to print and lightweight, but it has limited heat and impact resistance. It can be used for prototypes but is not recommended for final outdoor drone use, especially in hot climates where warping may occur.

PETG (Polyethylene Terephthalate Glycol-modified):

PETG is an excellent middle ground, combining strength, impact resistance, and slight flexibility. It resists cracking under stress and can handle sunlight exposure better than PLA.

ABS (Acrylonitrile Butadiene Styrene):

ABS offers good strength and temperature resistance but is prone to warping and requires an enclosure. It can work for drone parts but may be unnecessarily heavy compared to PETG.

Nylon (Polyamide):

Nylon is extremely strong, durable, and resistant to vibration fatigue. It is ideal for demanding drone parts but requires a high-temperature nozzle and precise print settings.

TPU (Thermoplastic Polyurethane):

TPU can be integrated in selective areas (such as vibration dampening mounts) but is too flexible for the entire stack holder.

Recommendation:

For most builders, PETG is the best choice due to its balance of strength, impact resistance, and ease of printing. For maximum performance, a hybrid approach of PETG structural parts with TPU vibration-dampening inserts is optimal.

Filament Settings for Best Results

Layer Height: 0.2 mm (balance of strength and precision).

Wall Thickness: At least 3 perimeters for rigidity.

Infill: 30–40% gyroid or honeycomb for strength with reduced weight.

Print Temperature: 235–245 °C for PETG (depending on filament brand).

Bed Temperature: 75–85 °C to ensure proper adhesion.

Cooling: Minimal part cooling (10–20%) to reduce layer separation in PETG.

Supports: Only where necessary (e.g., for port cutouts).

Adhesion: Use a brim or glue stick for PETG to avoid warping.

If printing in Nylon, increase nozzle temp to 250–260 °C, use 60% infill for maximum durability, and consider drying filament before printing.