Story

What is This Project About?

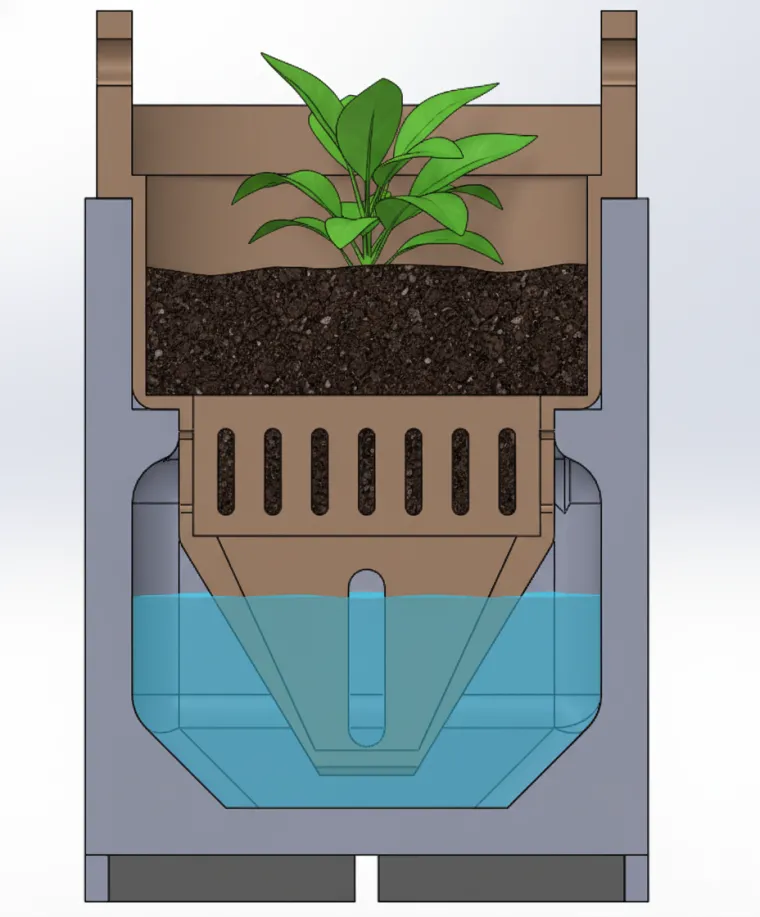

This project is a functional, 3D-printed prototype designed to solve a real, everyday problem: keeping plants alive in a busy urban environment. As a student in Davao City, I see many people (including myself and my peers in our robotics laboratory) who want to enjoy the benefits of indoor plants but struggle to find the time for a consistent watering schedule. This often leads to two main failures: Undewatering (neglect) and Overwatering (which causes root rot).

My goal was to take a proven concept, inspired by commercial products like the LetPot, and create a version that is accessible, customizable, and manufacturable with a standard FDM 3D printer. This Version 1 Prototype is the first step toward that goal.

How Does It Work?

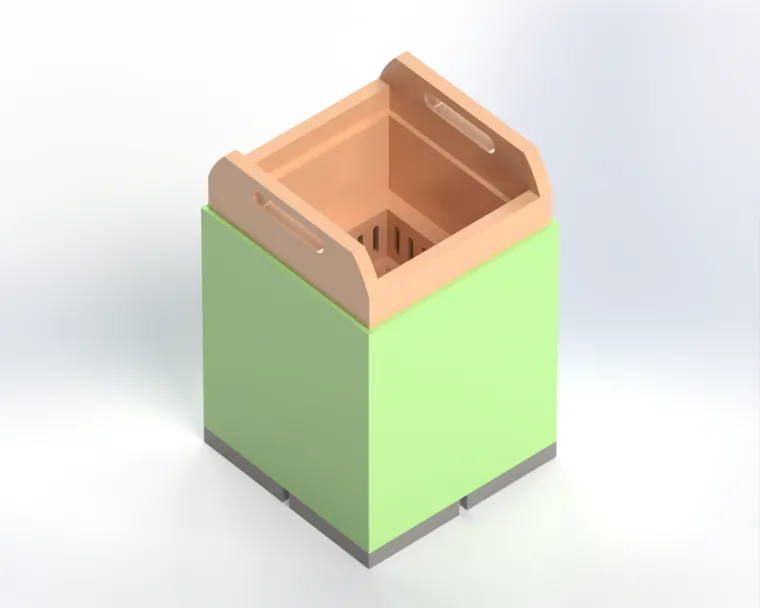

The design is a simple and reliable two-part system: an Outer Reservoir and an Inner Pot.

1. Large Water Reservoir: The Outer Pot holds a significant amount of water in a 2-inch-high reservoir at the bottom. This large capacity minimizes the need for frequent refills, making it perfect for busy owners.

2. Passive Wicking System: The Inner Pot, which holds the plant and soil, has carefully designed slits at its base.

3. Automatic Hydration: The soil uses capillary action to draw water up from the reservoir through these slits only as it's needed. This passive system provides the plant with a perfectly consistent amount of moisture, preventing both root rot from waterlogging and wilting from neglect.

4. Root Aeration: A critical feature of the design is that these same slits also allow for essential air circulation around the lower root system. This prevents the soil from becoming compacted and is key to long-term plant health.

From Prototype Version 1 to a Better Version 2: A Design Journey

Since this is a version 1 prototype, a "how-to-make-this" tutorial is premature. Instead, I want to share the key lessons from this design to help other makers in the community. This version 1 prototype served as a crucial benchmark: it proved that the fundamental capillary wicking mechanism works reliably.

Here are the common pitfalls and design considerations I'm focused on for v2, which I hope can help others:

1.) Pitfall 1: Balancing Wicking vs. Soil Containment. My primary concern was "Will the wicking even work?" I designed large slits to ensure the soil made good contact with the water. The good news: it works perfectly! The bad news: these large slits can allow some soil to fall through during the potting process.

1.1.) Lesson for version 2: I will experiment with smaller, more numerous holes or a "wicking cone" design (like my LePot inspiration ) that separates the soil from the water more cleanly while still allowing for strong capillary action.

2.) Pitfall 2: Designing for Water-Tightness. A planter cannot leak. My version 1 design relies heavily on specific print settings to be watertight. I used PETG-HF (for its water resistance), a 0.16mm layer height (for a smoother finish), and 3 wall loops to create a strong, leak-proof shell.

2.1.) Lesson for version 2: Instead of only relying on slicer settings, I will build water-tightness into the 3D model itself. This includes features like thicker walls by default and adding fillets/chamfers to the internal 90-degree corners, as sharp corners are often the first points of failure for leaks in a 3D print. and emphasize on the post processing part where a waterproof epoxy can be use.

3.) Pitfall 3: Print Time & Material Use. This version 1 prototype is a beast, taking just under 25 hours to print both parts. While its 6x6x8-inch size is great for a plant, it's a very long and material-intensive print.

3.1.) Lesson for version 2: I will focus on optimizing the geometry. For example, changing the square footprint to a rounded or circular one can often reduce print time and material (by eliminating sharp direction changes) without sacrificing the internal planting depth or reservoir volume.

This Version 1 prototype was a huge success. It confirmed the core concept and, more importantly, gave me a clear roadmap for creating a Version 2 that is more efficient to manufacture and even easier for others in the community to print and use.