Story

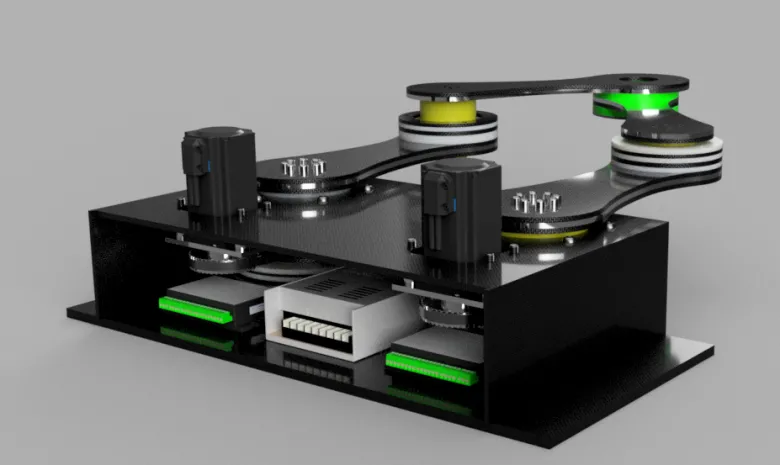

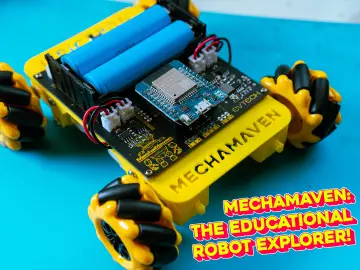

A low-cost, education-friendly SCARA robot with 3 planar DOF (base rotation + shoulder + elbow) and a position-controlled pneumatic gripper for Z/height pick-and-place. It’s designed around semi-mainstream components and hybrid fabrication: 2D CNC plates + FDM-printed brackets (nylon/PA or CF-nylon), assembled into robust 3D mechanisms.

How it works

-

Arm kinematics: Two coaxial revolute joints place the forearm; a third joint (wrist/forearm) aligns the gripper.

-

Parallel actuation layout: Motors are placed near the base with timing belts to keep moving mass low.

-

Z & grip: A compact pneumatic vertical slide or lift plus a position-controlled pneumatic gripper handles varying part heights.

-

Control loop: Encoders → controller (e.g., STM32/ESP32) → motor drivers → actuators; high-level commands come from a PC (Python) doing inverse kinematics.

Build it: step-by-step

0) Bill of Materials (typical)

-

Motion: 3× NEMA-17/23 steppers (or compact BLDC servos), GT2/HTD pulleys & belts, sealed radial bearings (608/6001), shoulder/elbow shafts, idlers.

-

Structure: 6–8 mm aluminum (or G10/FR4) plates for base/links, 3–4 mm for brackets; FDM-printed spacers, guards, wire guides (nylon/PA-CF).

-

Pneumatics: Mini cylinder or slide for Z, position-controlled gripper (with proportional valve or step-valve + pressure sensor), regulator, tubing, fittings.

-

Electronics: MCU (STM32/ESP32), stepper drivers (TMC5160/2209 or servo drivers), 24 V PSU, 5 V rail, limit/home switches, incremental encoders, e-stop.

-

Misc: Cable chain, ferrules, heat-set inserts, Loctite 243, thread-forming screws for plastics.

1) CAD & drawings

-

Lay out 2D plates (base, shoulder, elbow, motor/bearing plates) so they can be CNC-cut from sheet.

-

Add datum features (dowel holes/slots) to make alignment foolproof.

-

Export: DXF for plates, STL for printed parts.

Image to include: Exploded view labeling plates, printed brackets, and pulley paths.

2) Fabrication

-

CNC plates: 2D mill; deburr edges; ream bearing bores to size.

-

3D prints: Nylon/PA-CF, 0.2–0.28 mm layer, 4+ perimeters, 40–60% infill; orient to maximize fiber along load paths.

Image to include: Flat-lay of all cut plates + printed parts with part numbers.

3) Mechanical assembly

-

Press bearings into link plates; verify slip-fit shafts.

-

Build base: mount motors, idlers, and first-stage pulleys; route belts but leave slack.

-

Stack shoulder then elbow assemblies; install shafts and spacers; check free motion.

-

Tension belts (finger-tight + ¼ turn) and apply a drop of threadlocker.

-

Mount pneumatic Z slide and gripper; verify full travel.

Image: Belt routing close-ups; Short video (10–20 s): arm moving freely by hand.

4) Electronics & pneumatics

-

Wire MCU → drivers → motors; add home switches (base, shoulder, elbow) and an E-STOP in series with driver enable.

-

Plumb regulator → valves → cylinder/gripper; place a pressure sensor for closed-loop grip force.

-

Add strain relief + cable chain; keep air lines out of the work envelope.

Image: Wiring diagram; Video: power-on + E-STOP test.

5) Firmware bring-up

-

Set steps-per-rad (or encoder ticks/rad), max accel/velocity, and soft limits.

-

Home sequence: base → shoulder → elbow → Z; store offsets.

-

Expose a simple UART/USB API:

GOTO x y z θ,OPEN,CLOSE,SET_GRIP_FORCE.

Clip: Serial console showing commands and motion.

6) Kinematics & PC control

-

Implement inverse kinematics (IK) for SCARA: given (x, y) solve shoulder/elbow; wrist aligns tool angle.

-

Add workspace checks and singularity guards (elbow-up/down).

-

Python control script: teach points, linear move (interpolate in task-space), and pick-place sequence.

Video: Picks from tray A, places to tray B.

7) Calibration & testing

-

Link length calibration: move to gauge points, fit actual lengths to minimize IK error.

-

Backlash/belt tension: jog direction reversals; tune jerk/accel; retension belts if overshoot.

-

Pneumatic tuning: set regulator, valve PWM/step mapping, and grip force vs. pressure curve.

Image: Calibration fixture or printed jig; Clip: accuracy test placing pins into a pegboard.

8) Safety & enclosure (recommended)

-

Interlocked acrylic guard or light curtain; e-stop within reach; current limits set conservatively.

-

Label pinch points and add soft end-stops in firmware.